In 2012, the US corn harvest presented challenges for the country's farmers. In spite of testing every load coming in and rejecting many of them, some of the end products were tainted with aflatoxin, a naturally occurring poison that can cause serious illness or even death if consumed. Aflatoxin is the by-product of a mold that flourishes in dry conditions, and 2012's historic drought in the Midwest region put members of the agriculture industry on high alert.

Corn is a common ingredient for a range of petfoods and is a key feed grain for dairy and beef cattle, hogs and chickens, as well as a range of products for human consumption. While the potential for recalls due to contaminated product is not new, it reminds members of the petfood industry of the need for an integrated mycotoxin management plan to keep mycotoxins at bay.

In February, high levels of a potentially dangerous toxin were found in bags of dog food shelved at a Hy-Vee grocery store in Iowa. According to officials, the corn used had been tested before it was blended into the petfood, and Pro-Pet officials said they tested finished products, as well. But the contamination was not discovered until a random bag was pulled from a store shelf by an inspector for the Iowa Department of Agriculture. Subsequently, the Hy-Vee chain was forced to recall five different product lines of its food, which was manufactured at a Kansas Pro-Pet plant.

The sampling was part of a cooperative agreement that the Iowa Department of Agriculture forged with the U.S. Food and Drug Administration as an added measure to protect against aflatoxin consumption, according to Dustin Vande Hoef, a spokesman for the Iowa Department of Agriculture, the top U.S. corn-growing state. The Iowa Department of Agriculture is also requiring aflatoxin testing for milk.

Fortunately, no pets have been reported to have suffered illness from the recalled products, according to Ruth Comer, a spokesperson for the Hy-Vee grocery chain.

Pat Tovey, director of technology and regulatory compliance with the Pet Food Institute, identified aflatoxin prevention as a high priority in the industry. According to 2012 crop insurance data from the U.S. Department of Agriculture, payouts in 2012 for mycotoxins, of which aflatoxin is the most common, totaled nearly $75 million, tripling the level from one year ago. Nearly 85 percent of the claims were filed in six states: Arkansas, Illinois, Indiana, Kansas, Mississippi and Missouri.

The petfood industry is no stranger to recalled products due to mycotoxins. The earliest documented aflatoxin outbreak dates back to 1974 when hundreds of stray dogs in India died due to the consumption of aflatoxin-contaminated corn (Krishnamachari et al., 1975). In December 2005, 76 dogs were killed from aflatoxin-contaminated petfood in the US, causing a large recall.

Aflatoxins are predominantly produced by Aspergillus flavus and Aspergillus parasiticus molds. These molds can be formed both in the field and during storage and are commonly found in corn and peanuts grown in regions with high temperature and humidity. Aflatoxins can be harmful to pets if consumed in large quantities. The effects of aflatoxins and many other mycotoxins in dogs are listed in Figure 1.

Although testing for aflatoxins is carried out in many parts of the world, outbreaks still occur. The reason can be sampling error, as 85 percent of mycotoxin analysis error stems from a sampling error.

Quick mycotoxin tests, based on ELISA principles, are commonly employed at petfood plants to accept or reject food ingredients. Although these tests provide instant results and are cheap, they are semi-quantitative in nature. This means the quantification is not accurate and may result in levels of toxin above the recommendation in the petfood.

If grains are not stored in appropriate conditions, aflatoxins can form in petfood during storage. Other mycotoxins, such as ochratoxins, deoxynivalenol (DON or vomitoxin), T-2 toxin, zearalenone and fumonisins, can develop during the storage period. These mycotoxins can increase the chances of aflatoxin outbreak because they can interact with aflatoxins.

Mycotoxin management is an integrated program, and all the factors related to mold growth, mycotoxin production and negative effects on the animal should be taken into consideration. There are three key components to this program: assessing the risk to the best possible extent; controlling and managing all the critical points of entry of mycotoxins into the dog food chain; and continual innovation of mycotoxin management programs capable of addressing mycotoxin challenges.

37+ mycotoxin program

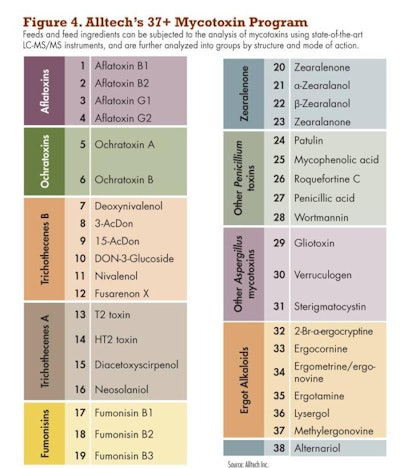

Although many laboratories across the world are trying to increase the number of mycotoxins tested, most of the analyses are tested for the six primary mycotoxins. Alltech has developed a 37+ mycotoxin program wherein feeds and feed ingredients can be subjected to the analysis of 38 mycotoxins using state-of-the-art LC-MS/MS instruments. For a better understanding of toxicity, these mycotoxins are further analyzed into groups by structure and mode of action (Figure 4 ).

There have been 965 samples analyzed to date. The samples included grains, protein sources, by-products and animal feeds, including dog food. Some of the key findings are:

- 98% of the samples were contaminated with one or more mycotoxins.

- 93% of the samples contained two or more mycotoxins.

- 39% of the samples contained more than five mycotoxins.

- 80% and 73% of the samples contained fumonisins and DON-Group of mycotoxins, respectively (Figure 2 ). Three other groups of mycotoxins were present in more than 30% of the samples.

- The concentrations of DON-Group, T-2 Group, fumonisins and Zearalenone-Group were in significant enough concentrations to cause toxicity in dogs (Figure 3 ).

HACCP approach to mycotoxin management

Mycotoxin management starts right from the time the crops are on the field and continues through harvesting, transportation, storage, milling and feeding. Alltech's MIKO program was launched to assist petfood manufacturers. Based on HACCP (Hazard Analysis Critical Control Point) principles, the program is designed to identify the mycotoxin risks within a given plant and create a program to minimize the potential risks to companion animals.

The goal of MIKO is to understand the level of mycotoxin challenges entering the supply chain so that the right steps can be taken to mitigate the negative effects on animal performance. This involves setting up the correct grain and food monitoring procedures, as well as identifying critical mycotoxin limits for petfood. With this information, the health and well-being of pets can be protected from mycotoxin exposure.

Broad-spectrum mycotoxin management

Even when producers follow correct monitoring procedures, mycotoxins are unavoidable in petfoods. Unlike nutrients, mycotoxins are not uniformly distributed in foodstuffs, which make accurate analysis difficult. A risk management approach should contemplate the use of a mycotoxin management program capable of coping with that chance of having a mycotoxin contamination issue.

With significant advances in mycotoxin analytical techniques, members of the petfood industry are more equipped than ever to detect very small concentrations of mycotoxins. These advances necessitate more vigilance in setting up measures to prevent entry of mycotoxins into the petfood chain. Farmers, manufacturers and petfood industry officials should apply control measures in the fields where crops are grown, the mills where petfood is produced, and finally, to the consumer level where mycotoxin can enter an animal's blood circulation.