Petfood manufacturers and the testing labs hired by them are under increasing pressure to take petfood testing to a new level. How should expectations for petfood testing be raised and enforced in the global ingredients supply chain? How can your company better safeguard against product contamination? And perhaps most importantly, how can public confidence in the petfood products you produce be maintained with advanced scientific proof to support it?

"Companies and government agencies need to monitor more food products and raw materials from an increasing variety of new sources -- which may face contamination linked to storage issue or the use of pesticides or other substances, which are banned in one country but allowed in another," explains Mark Kuracina of Applied Biosystems. But what does he recommend? "Expanding the capacity to test for contaminants by upgrading the technology is logical." The good news is that the technology for petfood contaminant testing is changing for the better. Technical advancements are unfolding as government policy-makers devise new frameworks for ensuring petfood safety.

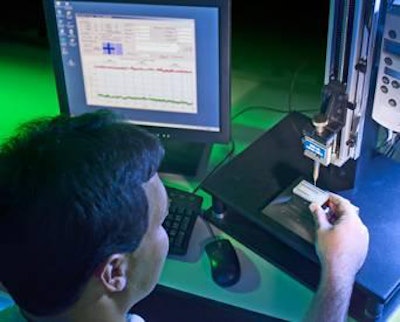

Take, for example, Perten Instruments' Micro Mirror module. The module is a sample presentation system for the DA 7200 that enables analysis of extremely small samples. The Micro Mirror module is designed for small sample amounts such as kernels, seeds and powders or meals.

More small, handheld devices for accurate and easy-to-read test results are the family of sample adapters for the patented i-Lab analyzing spectrometer from MicroOptix Technologies. The i-Lab performs measurement and analysis of liquids and solids in the visible light range of 400-700 nanometers, according to the company.

The Teledyne Tekmar Atomx Automated VOC Sample Prep System combines an autosampler and purge and trap into a single instrument for the analysis of volatile organic compounds, with the ability to perform methanol extractions. The system features the Extractasol clean-up step to reduce carryover or cross contamination.

Buchi Corp. offers the NIRMaster, a standalone FT-NIR spectrometer with hygienic design for petfood and feed applications. It is available in food-grade polymer and stainless steel housings (both in protection class IP54 and IP65). Its polarization interferometer provides high sensitivity and robustness.

Processors and packagers in the petfood industry face certain challenges, including detecting contaminants, detecting damaged or missing products and identifying overfill and underfill. Mettler-Toledo Inc. offers its X-ray Inspection technology presentation, entitled X-ray Inspection - The Future of Packaging Inspection. The comprehensive presentation, available for download, explains the technology and its specific application to the industry, as well as demonstrates that X-ray provides capabilities not available in metal detectors or vision systems.

Over 23,000 tons of petfood was recalled between 2006 and 2008, according to a study conducted by the Centers for Disease Control and Prevention (CDC). Bio-Rad Laboratories iQ-CheckTM Salmonella II kit has recently received AOAC approval for real-time PCR detection of Salmonella from wet cat food, dry dog food, stainless steel, plastic, ceramic and concrete. This represents a Performance Tested Method matrix extension for the iQ-Check Salmonella II kit, which is currently approved for raw chicken, raw beef, eggs, cantaloupe and peanut butter.

The performance of the iQ-Check kit was compared to the Food and Drug Administration Bacteriological Analytical Manual (BAM) reference method for detection of Salmonella from the petfood and environmental surfaces. There was no significant difference between the performance of two methods. All samples that were detected as positive by iQ-Check were confirmed by the reference method, according to the company.

Vicam offers Vertu, a digital lateral flow technology for quantitative mycotoxin screening. The Vertu reader is designed to provide more accessible mycotoxin testing to producers who rely on early detection to protect from contamination. Results are in parts per billion or parts per million. Is your brand protected?