Manufacturing the best-quality dry petfoods for dogs and cats not only relies on a nutritionally sound formula, a solid marketing campaign and eye-catching packaging, but it must be produced in a cost-efficient, time-saving and sanitary way. That's why choosing the right extrusion, drying and cooling equipment is so vital. Whether you are a company on its puppy legs, looking to start out with small batches and simple formulas, or an industry player who needs to update its current manufacturing line, new and innovative products are available to help meet your specific needs.

Baker-Rullman Mfg. Inc. is a maker of rotary drum dryers and dehydration systems. The company points to its triple-pass technology used in its dryer systems as an optimizer of operating costs, efficiency and end-product consistency and a reducer of VOC emissions. The three full-length interlocked concentric cylinders in this technology rotate together for the highest velocity in the inner-pass. As lighter particles quickly lose 60% of their moisture and move out of the cylinder, heavier, denser particles are retained until they lose 60% of their moisture. Because of the earlier retention time in the first two passes, material is relatively uniform by the time it makes it into the gentle third pass. This means the product is guarded against over-drying or under-drying and ensures the optimum use of heat while producing a consistently high-quality end product, according to the company.

Buhler Aeroglide Corp. offers a wide range of dry petfood and treat manufacturing equipment, including dual plenum roasters and dryers and single/multi-pass conveyor dryers. Benefits of a plenum roaster include sanitation features with full welds, complete interior access and elimination of debris collection points. The roaster's uniform heat and airflow distribution eliminate the need for diffuser plates, according to the company. With the multi-pass dryers, conveyor beds are stacked one above the other in a single insulated enclosure. The systems provide multiple product turnovers for uniform thermal processing. They can also be configured to run at the same temperature throughout or with sequential heat zones allowing precise control of temperature, process air humidity and airflow throughout the process.

Clextral Inc. is a maker of dryers and extruders, including the Rotante dryer and Evolum line of extruders. The Rotante dryer features product changeover in less than three minutes, real-time recycling of fines generated in the drying process, simplified cleaning and reduced maintenance, according to the company. The Evolum 145 (EV145) extruder incorporates advanced temperature control for managing complex recipes in the processing of premium dry and semi-moist petfoods. The Evolum 25 (EV25) is an extruder designed for product testing, reliable scale up to production extruders and to assist petfood processors in developing new extruded products. This twin screw extruder is useful for producers looking to develop dry petfood, semi-moist nuggets, treats and premium petfood with a wide array of densities, textures, shapes and colors.

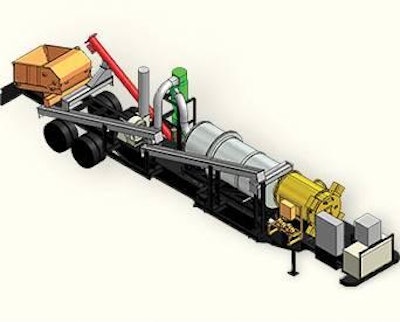

Extru-Tech Inc. has installed numerous extrusion systems worldwide, supplies the industry with quality replacement parts and manufactures extruders, dryers and coolers for the petfood industry. The company's newest technology is the Maxxim series of extrusion systems. This line of single screw extruders is capable of 20% to 30% production rate increases over previous models with the same barrel diameter, according to the company. Extru-Tech's re-engineered inline drive system can handle up to 600 hp and the improved screw support assembly eliminates metal-to-metal wear.

Radio Frequency Co. offers unique, Macrowave post-baking dryers that utilize radio frequency energy to heat and dry moist areas of food. Macrowave dryers, according to the company, eliminate surface checking and control moisture and color. The dryers were developed for high-volume production and are available in band widths up to 64 inches.

Wenger Manufacturing has long provided extrusion, drying and cooling systems for the industry. Its newest innovation is the Enhanced Sanitary Dryer. The dryer was designed to reduce the risk of contamination, according to Wenger. The company also says the design criteria for the new dryer stated that no internal horizontal surface could be larger than 5-by-5 mm unless absolutely necessary. The design also called for a minimum 30-degree slope on all internal ledges and the elimination of cracks and crevices in which fines and material could collect.