Juiciness is the ability of meat to release juice (defined as the quantity of water preserved after cooking) when a pet chews it. Most of the juiciness in meat is actually water, but the sensation of juiciness happens two ways: The first corresponds to the quantity of juice that is released into the mouth when the meat is first chewed, and the secondary perception of juiciness is due to salivary flow stimulated by the presence of fat in the mouth. Juiciness or succulence is well correlated with improved palatability and enjoyable eating for humans and our pets.

A correlation between cooked meat, juiciness and water content with special emphasis on the extent of binding of water to coagulated tissue was reported in the 1960s. The water-holding capacity (WHC) is the ability of meat to hold its own or added water during the application of any force. There is a positive correlation between WHC and juiciness of cooked meat, and a noted increase of juiciness associated with higher water content of meat and tighter binding of this water to tissue.

New research shows that spray-dried plasma (SDP) is a superior binder for wet petfood, says APC Europe, and is characterized by its well-balanced technological properties that work well in wet petfood products. Spray-dried plasma has high gelling, water retention and emulsion capacities compared to other binders. Due to the very high water holding capacity of SDP, it is an excellent candidate to improve the juiciness and palatability of cooked chunks and pouches.

To demonstrate the improved juiciness properties of SDP, a study was conducted comparing two binders, SDP (AP820PF from APC Europe) included at 2% in the recipe or wheat gluten (WG; Viten, Roquette Laisa España SA) included at 2%, 4% and 6% in the recipe and compared to a control diet without binder. The experiment was performed for three consecutive days. See Table 1 for the particular chunk wet petfood recipes used in the study.

We prepared cans with chunks of similar size and shape, produced with a special device and included in gravy containing 0.8% pork stock (Proliant P1301 from APC Europe), 0.15% iota carrageenan and 99.05% water in a ratio of 48:52 between chunks and gravy. Eight to 10 chunks (35x17x30 mm) per can were weighed before adding the gravy. Four cans per treatment were sterilized in a laboratory autoclave at 121°C for one hour and cooled to room temperature for two weeks before performing the analysis.

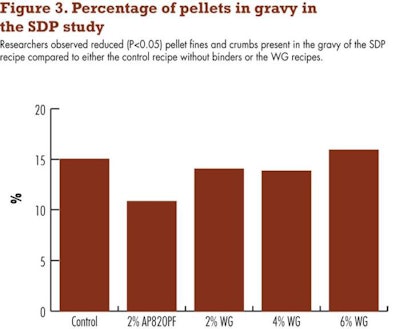

The juiciness was analyzed as a "cook in" concept, defined as the amount of gravy that was absorbed by the chunks after cooking and corresponding to the change in weight of the 8-10 chunks of each can after cooking and storage during two weeks. We also analyzed the turbidity or "cook out" effect, defined as the percentage of product that can be exudated from chunks to the gravy after cooking. We analyzed this cook out effect as the percentage of pellet obtained after centrifugation of the gravy collected from each can at 15,000 rpm during 30 minutes.

The hardness and other texture profile parameters (chewiness, cohesiveness, adhesiveness and resilience) of the chunks were also measured after submitting five chunks per can to two cycles of compression separated by two seconds, both at the same constant speed of 0.5 mm/s and 50% of strain.

As expected, the hardness of the chunks as related to texture of the product was improved (P<0.05) with the addition of SDP to the recipe (Figure 1). The addition of SDP improved the hardness of chunks by 2.5 times compared to the control recipe without binders. Also, a higher hardness (P<0.05) for the SDP recipe was observed compared to wheat gluten recipes regardless of wheat gluten inclusion level.

We also observed that SDP improved (P<0.05) the cook in juiciness effect (analyzed as percentage of gravy absorbed in chunks) of the cooked chunks when compared to either the control or the wheat gluten recipes (Figure 2). We observed that SDP improved the juiciness by 168% compared with the control recipe and between 115 to 140% compared with wheat gluten recipes.

Also, we observed reduced (P<0.05) pellet fines and crumbs present in the gravy of the SDP recipe compared to either the control recipe without binders or the wheat gluten recipes (Figure 3).

The use of 2% SDP in recipes improved the juiciness of cooked chunks in gravy and juiciness is related with improved palatability of the chunks, as already has been described including plasma in wet petfood diets (Polo et al., 2005). Plasma also reduced fines, crumbs and the turbidity of the gravy, which can be related with better quality of the final product from the perception of the petfood consumer.