For more than 50 years, application of the principles of HACCP (Hazard Analysis Critical Control Points) has been widely accepted as the most effective means of ensuring the food we eat is safe. Through regulatory and voluntary controls, HACCP is also applied globally throughout the pet food supply chain to ensure pet food safety.

Pet food safety is a shared responsibility across regulatory, operational and consumer levels of control. At operational level, standards enable us to voluntarily demonstrate to regulatory authorities that we comply with regulations, industry standards and codes of practice. They also demonstrate that our products are “fit for purpose;” i.e., they are safe for our pets to eat, thereby enhancing consumer confidence.

Standards do not guarantee pet food safety nor do they prevent occurrence of pet food safety incidents. Conceptually they provide a framework of procedures to ensure that food safety hazards are identified, controlled and monitored to ensure food safety management system (FSMS) effectiveness. To build and maintain consumer trust in pet food safety, a further requirement is continuous improvement where we evolve our FSMS to identify and control new hazards and risk as these occur.

Broadly speaking, we can think about pet food safety standards as falling into four categories: independent standards, third-party commercial standards, industry standards and retailer standards (see Figure 1).

There are several types of voluntary food safety standards out there. Determining what best suits the needs of your company will require thought and consideration for the market you’re serving.

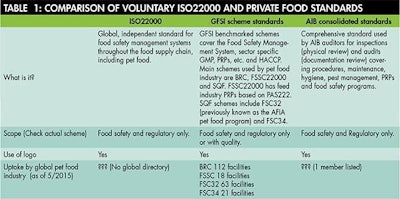

This diversity can give rise to the perception that a harmonized, standardized approach to food safety standards is lacking globally. This is overcome through the use of either the globally accepted, independent ISO22000 standard or through the schemes recognized by the Global Food Safety Initiative (GFSI). Established in 2000, with stakeholder representation throughout the food supply chain, academia and regulatory authorities, GFSI was established to benchmark standards to ensure a common approach and equivalence in managing food safety.

It should be noted that not all standards are recognized by GFSI. When originally benchmarked by GFSI, the ISO22000 food safety standard per se did not satisfy the GFSI criteria on the pre-requisite programs (PRPs). To address this deficiency, the FSSC22000 (Food Safety System Certification 22000) organization developed FSSC22000, and this was approved by GFSI in 2013 for human food. This builds on ISO22000 plus sector-specific PRPs; e.g., PAS222:2011 (PRPs for animal feed manufacture). In addition, SQF's FSC32 and FSC34 are GFSI-benchmarked for pet food and animal food, respectively.

Many different internal and external motivations and drivers exist for implementation of standards (see Figure 2). For example, these can be a prerequisite to becoming an approved supplier to a specific retailer; e.g., “Walmart Food Safety Requirements for Pet Food.” Other than highlighting their potential link to voluntary schemes, retailer standards will not be discussed further.

There are many motivations and drivers that might lead a manufacturer to look into any or all the available certifications from various entities in the pet food industry.

Another powerful driver is building consumer trust. Critically this also requires communication (internal and external) that is a cornerstone of many standards including ISO22000, BRC, SQF and FSSC22000.

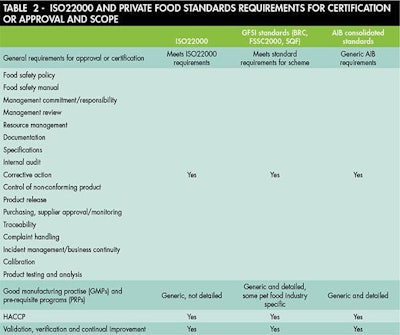

There are four different types of primary food safety standards, including ISO22000, GFSI schemes such as SQFI FSC32 and FSC34, AFIA programs such as FSC36, and the AIB Consolidated Standards (see Table 1, Table 2).

Broadly speaking, these all have the same aim: to ensure the production of safe pet food, through covering food safety and regulatory aspects. However, some schemes (SQF, AFIA and BRC) also cover quality management systems.

Table 2 indicates that most PRPs and GMP are generic (similar scope), but the depth of information varies (e.g., ISO22000 has generic PRPs lacking in detail, whereas GFSI schemes are more detailed). Only three schemes have feed industry specific PRPs/GMP: FSSC22000 (PAS222:2011 requirements on PRPs for the animal feed sector), the pet food-specific SQFI FSC32 scheme and the animal feed-specific SQFI FSC34.

Superficially, most schemes seem to be similar. How, then, do you choose a third-party food safety scheme? To maintain impartiality, it is inappropriate to recommend a particular scheme in this article. However, based on experience in the human food sector, some guidelines can be proposed:

· Know your customer – What are your retailers’ preferences/requirements?

· Certification body – Find one who will guide you and support you through the certification process and beyond.

· Organizational capabilities – Find a scheme that fits your capabilities; e.g., availability of trained internal auditors or food safety experts.

· Scope – Do you require quality to be covered with food safety and regulatory?

· Sector specific or generic – Do you want a generic (food) or feed/pet food sector specific scheme?

As the global petfood industry continues to grow, we still have an undercurrent of loss of consumer trust in our ability to ensure pet food safety. Given the relatively low implementation, this leaves pet food producers with a big question to answer: Can we really afford not to have third-party food safety certification?

The different voluntary third-party food safety standards vary in their scope and current adoption by the global pet food industry.

Many of the requirements for the various third-party safety standards overlap, making multiple-certification a significant possibility for manufacturers looking to expand their voluntary regulatory compliance.

Barriers to implementation of third-party food safety standards

It is interesting to note that only a small proportion of pet food manufacturers globally are certified to a recognized third-party food safety standard. Why? A review of the scientific literature gives us some insights on the potential reasons for this and shows that barriers to implementation fall broadly into the following categories:

• Lack of resources – Money, time, people

• Training – Lack of food safety skills and expertise

• Lack of motivation – Senior management commitment and engagement by employees

• Lack of external pressure – No regulatory pressure to enforce producers to have third-party certification (HACCP only); customers not forcing suppliers to implement third-party food standard

Unless these critical success factors are addressed, extensive research shows that implementation of a successful food safety management system is reduced.

The lack of external pressure is an interesting factor. As we have seen earlier, certification to a recognized GFSI scheme is a pre-requisite for supplying pet food to some retailers. On the plus side, certification can bring many business benefits, ranging from increased consumer trust and increased sales to reduced costs and increased staff motivation. These help balance the costs of implementation and maintenance of a certified food safety management system.