Complete and balanced pet foods are extruded to provide a shelf stable, resilient, palatable and pasteurized product as a highly digestible delivery mechanism for the essential nutrients companion animals require.

Traditionally, continuous cooking extruders utilize a combination of mechanical and thermal energy inputs to gelatinize the carbohydrates binding the other ingredients and forming the finished kibble product. Typically, equal-to-higher inputs of mechanical to thermal energy are used to extrude these products. With the continued market trend to increased meat inclusion, unique carbohydrates and product differentiation, as well as the continual rise in energy costs, the use of significantly higher levels of thermal energy inputs has provided a new way of extrusion cooking. Producing extruded pet foods with high thermal energy and low mechanical energy provides operational flexibility, production cost reduction and nutritional benefits over traditional high mechanical energy processing.

Production-related benefits:

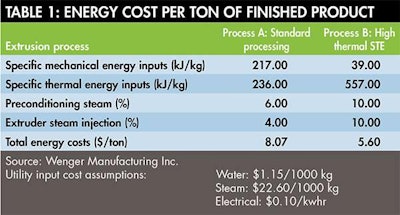

1. Lower energy cost per ton of finished product (see Table 1)

· Electrical (mechanical) energy costs more per unit than thermal energy.

· By increasing the thermal to mechanical ratio, the energy cost per ton goes down.

Extruding pet foods with high thermal energy and low mechanical energy has several production benefits, including a lower overall energy cost per ton of finished product.

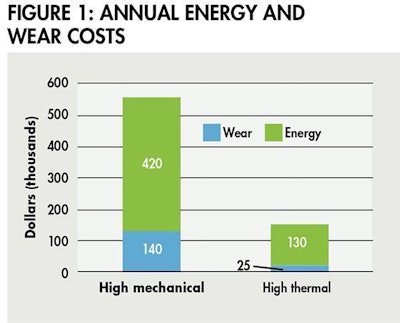

2. Lower wear cost per ton of finished product (see Figure 1)

· Mechanical energy is friction, and friction is wear, so cooking with higher mechanical energy yields much higher wear costs.

· Typical wear costs is $1.25/ton per 22 kWhr/t of SME.

· Traditional extrusion requires 25–40 kWhr/t of SME.

· New thermal cooking extrusion requires 8–15 kWhr/ton of SME.

Another production-related benefit is a lower wear cost per ton of finished product.

3. Process flexibility and wider range of production capability

· Thermal energy cooking with the appropriate equipment and hardware has proven to produce using a wider range of materials and recipes, yielding stable, commercially viable pet food.

· High carbohydrate (>60%) production without extruder surging and sticky product at the die, typical of that of high mechanical energy processing.

· Low carbohydrate (<15%) production with resilient product.

· Ultra-high meat slurry inclusion of greater than 50% of the complete formula.

· Grain-free diets with unique inclusions of beans, pulses and vegetable proteins.

· High-fiber diets utilizing the increased thermal energy in melting the fibrous ingredients, allowing for a more stable process.

Nutritional-related benefits:

1. Through a series of feeding trials, no significant differences in kibble technical qualities, such as digestibility, strength, fecal quality and palatability, for varying mechanical and thermal energy inputs.

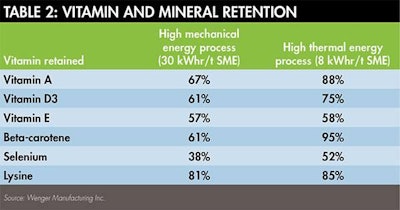

2. Improved vitamin and mineral retention (see Table 2).

One of the nutritional benefits of extruding pet foods with high thermal energy and low mechanical energy is improved vitamin and mineral retention.

Understanding all this data is not valuable if there is not capability to produce with high thermal energy inputs. So, what is available for manufacturers to produce with this new cooking strategy? There have been significant developments over the last several years in preconditioning and twin screw technology to support a process with upwards of a 12-to-1 thermal to mechanical energy ratio.

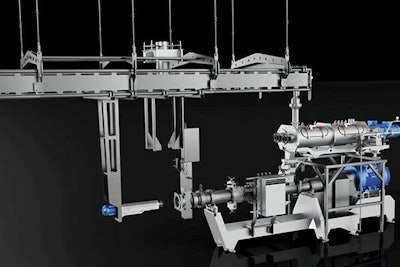

For example, Wenger’s patented high intensity preconditioner feeding a thermal twin extruder make this process a feasible and proven solution. The design of this equipment allows for very high steam inclusion that is effectively absorbed into the product and changes the cooking profile, allowing for ultimate process flexibility.

The preconditioner utilizes an integrated injection system for steam and water, allowing for inclusion of steam up to 14%. Additionally, the ability to vary the speed, beater contacts per minute and ultimately the mixing intensity allows for flexibility in targeting a specific mixing level on an individual formula basis. The extruder utilizes multiple steam injection points down the length of the extruder and a unique twin screw configuration, allowing inclusion of steam up to 10%. The extruder speed can also be varied to dial in specific formula process settings.

Courtesy Wenger Manufacturing Inc.

Production-related benefits of using higher thermal energy levels and lower mechanical energy levels in pet food extrusion include lower energy cost, lower wear cost, process flexibility and a wider range of production capability.

As pet food companies continue to develop unique differentiating products that will undoubtedly require more ingredients and process flexibility, there is now an option for manufacturers to meet these demands utilizing the thermal twin process. Inherently, the movement from mechanical to thermal processing provides benefits from energy and wear cost savings, as well as nutrient retention superior to that of traditional high mechanical energy cooking.

For the latest on pet food extrusion