DryingPro, a smart drying process control that tightens moisture tolerances in accordance with defined targets.

Brand Insights from Buhler Group

Today’s margins in food and feed processing are tight. At the same time, more and more of today’s companion food buyers are demanding that processors have a more sustainable approach to their production, often leading to the need to reduce CO2 emissions. In this environment, the impact of every decision a processor makes can be magnified and quickly become harder to manage. Seemingly small decisions made by an operator can have enormous effects on both margins and a company’s sustainability initiatives, not to mention fluctuating product quality.

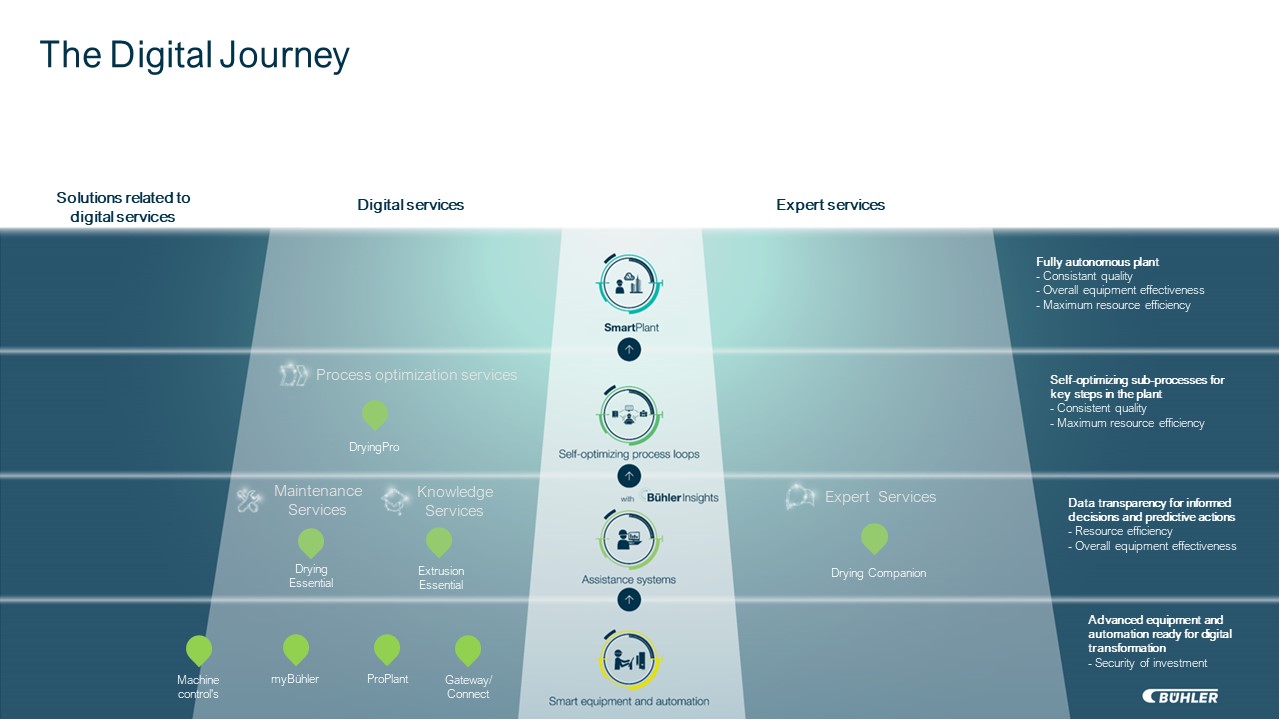

It's here, at this juncture of the business needs of production, and the brand’s needs to meet consumer demands, that digitalization can help a processor deliver on both fronts. Employing digital tools helps a processor to not only make better, data-driven decisions, but also helps them maintain an optimum production environment consistently, across all sites, shifts, and SKUs.

Production

The smallest percentage gain in your production process can make a big difference in more than one aspect of your business. Getting the right moisture content in your product is one way to quickly achieve these gains. If you don’t dry your food or feed enough there’s too much moisture and the risk of contamination from mold. Over-drying wastes energy and increases waste, using more raw materials for each bag produced.

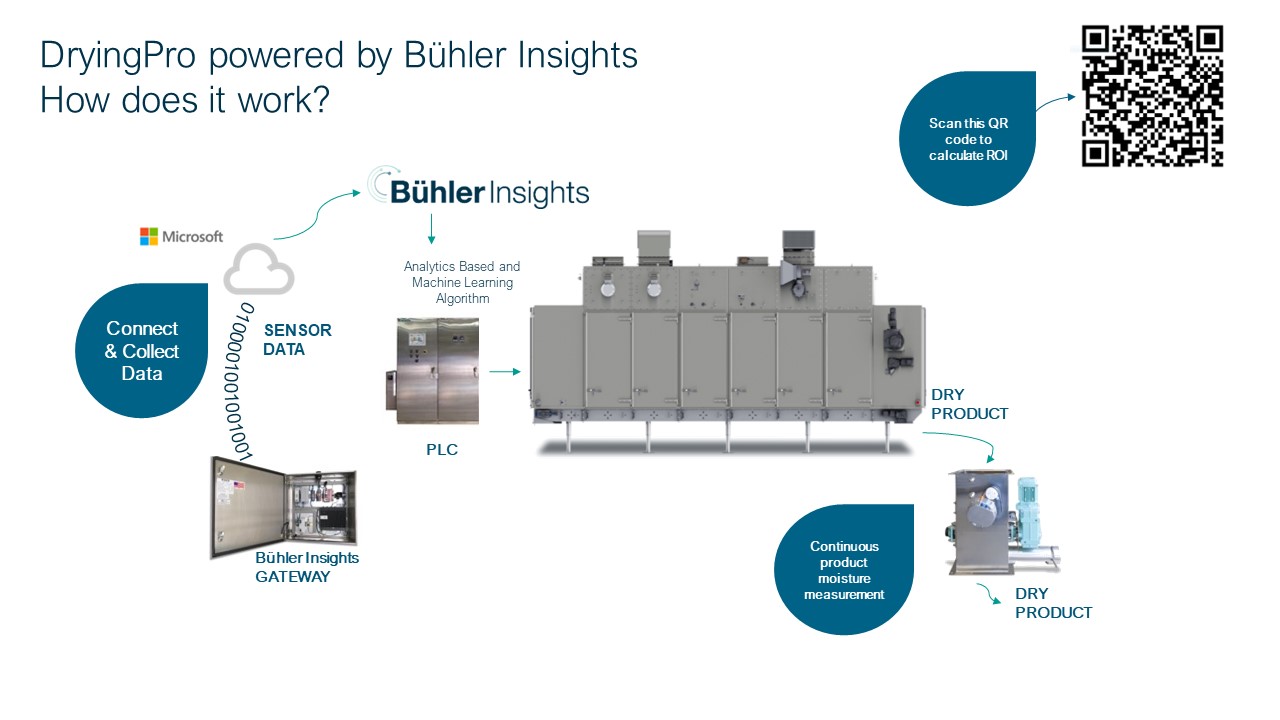

Powered by Bühler Insights, Bühler’s central platform for connected products and services, DryingPro Moisture Control enhances the dryer operation by optimizing drying performance, bringing the product closer to target moisture. One result of this is a consistent, high-quality product. Fluctuations in moisture content are eliminated, allowing for greater uniformity across the production run. This also increases overall yield by preventing over-drying, while eliminating the risks associated with under-drying.

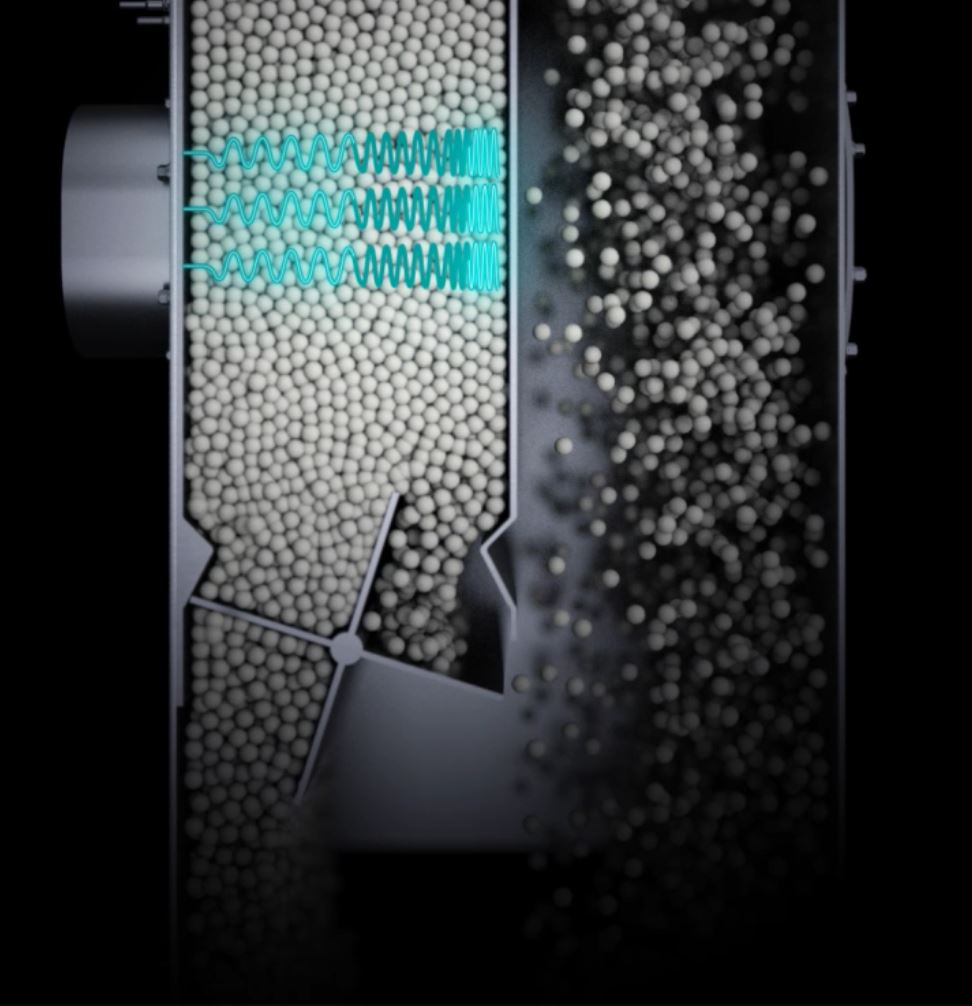

To improve the quality and get a more stable output from the dryer, an in-line microwave technology is applied that constantly measures moisture content:

- As product is discharged from the dryer, it passes through an analysis chute where approximately 20% of it is diverted to the sensing chamber.

- A rotating gate at the bottom of the sensing chamber slows the flow of product.

- A high-performance microwave sensor tailor-made for this application gathers moisture data and sends it to the Drying Pro control panel.

Moisture content targets can be input by operator or by recipe control, and the dryer will automatically establish and maintain the optimal drying environment for the remaining production run. This eliminates the wasted energy and product that can result from manually attempting to reach a moisture target.

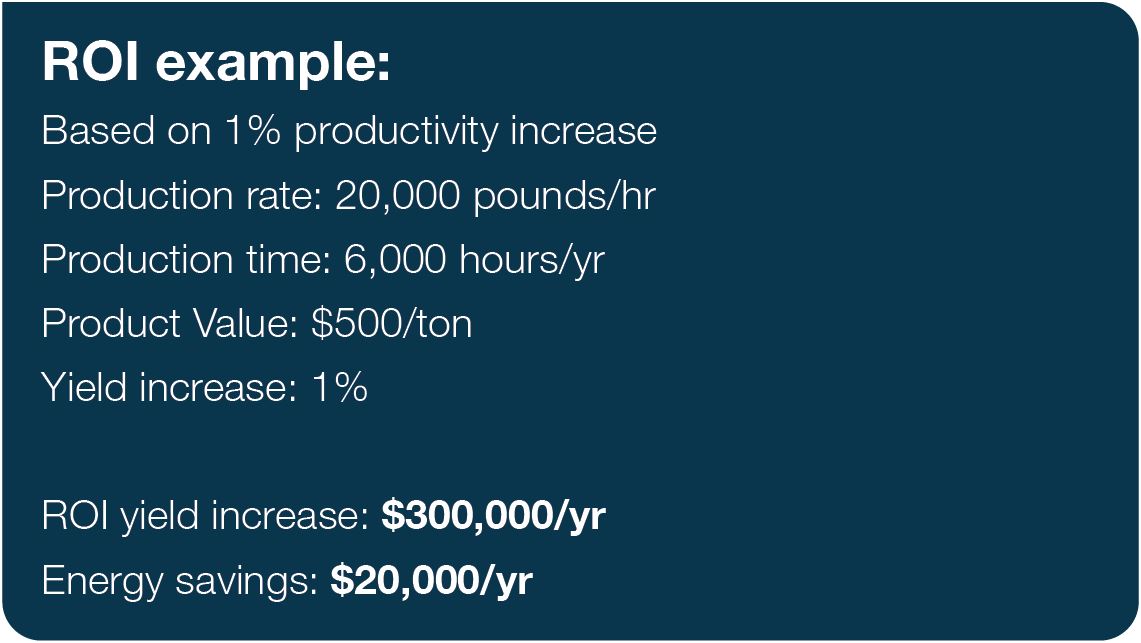

And the return on investment for DryingPro can be very quick, as well, based on a conservative 1% increase in yield.

Current safety margins in the moisture content of extruded pet food are +/- 1.5%. By employing DryingPro, that range can be reduced to +/- 0.5%. As well, fluctuations in the moisture of ingredients have a direct impact on the moisture content in the product coming out of the dryer. Utilizing this digital tool can reduce the impact of such moisture changes while keeping the operation consistently within the safety margins.

Sustainability

The better equipment performance and lower energy consumption that DryingPro helps to deliver, reduce operating costs, and improve a business’s environmental footprint. But it’s not all about energy, though. When the drying process is optimized continually, and the dryer is producing a consistent product with the targeted moisture content, raw material usage is optimized, as well. Waste from inefficient use of raw material is reduced since less finished product is required to fill the bag and meet weight requirements, versus when the product is over-dried.

DryingPro and the larger portfolio of digital tools within the Bühler Insights platform can deliver results for a processor who is looking to improve production and product quality while supporting corporate sustainability initiatives. To learn more about how these tools can help your organization, contact Bühler at [email protected] or read more about DryingPro here.