Discover how pet food manufacturers are reducing emissions and driving sustainability through ingredient innovation and eco-friendly nutrition.

Brand insights from Datacor

Sustainability has become a significant consideration—and opportunity—of modern pet food production. As consumers demand greater transparency and governments introduce stricter environmental targets, manufacturers are under pressure to deliver nutrition that’s not just high quality but also low impact.

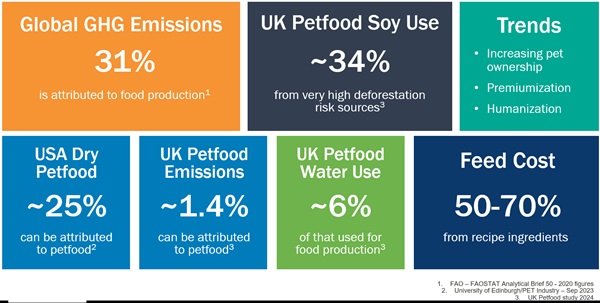

According to the Food and Agriculture Organization (FAO), food production accounts for roughly 31% of global greenhouse gas (GHG) emissions,1 and research indicates pet food contributes up to 25% of that total.2 Research in the UK shows that the pet food sector represents about 1.4% of national food-related emissions and 6% of total food-sector water use—and roughly a third of soy used in pet diets comes from high-deforestation-risk regions.3

Global and UK data illustrating share of greenhouse gas emissions and water use from pet food production.

For pet food manufacturers, the challenge is clear: meaningful sustainability gains won’t come solely from packaging or transportation initiatives—they must begin where every product begins: with the formula itself.

The Hidden Impact of the Formula

Ingredients define both the nutritional and environmental profile of every recipe. They also drive 50–70% of total production cost, making them the biggest lever for both profitability and sustainability.

Each ingredient carries its own environmental footprint—varying in land use, water consumption, embedded carbon, and more. These are significant when examining ingredients used in large quantities, like high protein ingredients such as meat meals, fishmeal, and certain plant proteins. When manufacturers can see these metrics during formulation, they can make smarter trade-offs between performance and environmental impact.

Modern formulation systems can now integrate lifecycle analysis (LCA) data directly into recipe development, allowing teams to track metrics such as GHG emissions, land use, water intensity, and deforestation risk in real time. This integration transforms formulation from a cost-management tool into a sustainability decision engine.

You can’t improve what you don’t measure—and now, formulation software brings sustainability metrics directly into ingredient selection.

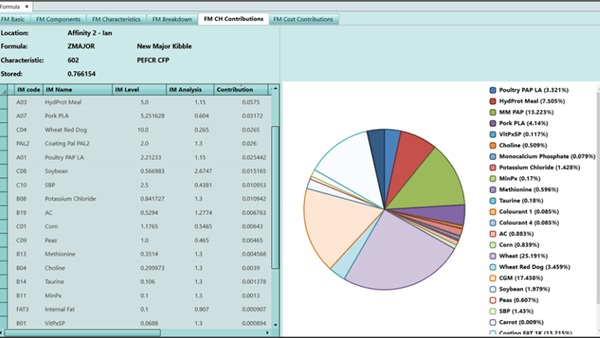

Example analysis of the source of the Carbon Footprint within a formula

Measuring What Matters

When formulation and LCA tools work together, manufacturers gain a precise understanding of where their environmental impact originates.

They can benchmark each recipe, identify high-impact ingredients, and model the effects of ingredient substitutions before they happen. This not only informs internal sustainability goals but also supports regulatory reporting and customer transparency—both increasingly essential for access to major retail channels.

By embedding environmental data into daily workflows, pet food producers move from reactive compliance to proactive sustainability management.

Optimizing for Sustainability

Traditional formulation focuses on balancing cost and nutrition. Sustainability adds a third critical dimension: environmental optimization.

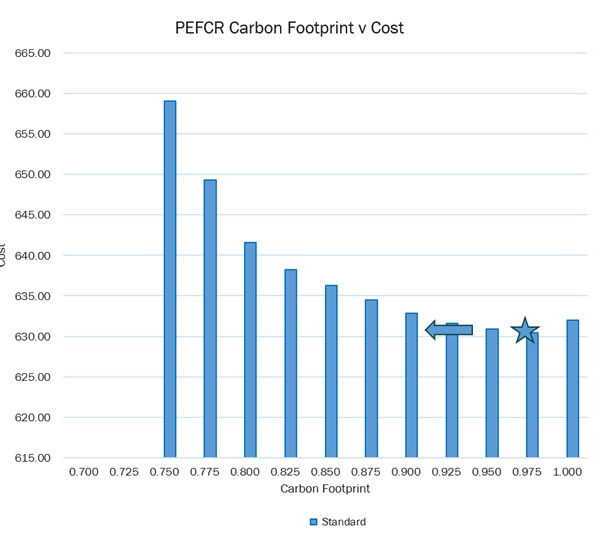

Using multi-objective optimization, manufacturers can now model scenarios that balance all three—cost, nutrition, and carbon footprint—simultaneously. For example, they can test whether switching from a high-impact soy source to an alternative protein reduces emissions enough to justify a modest cost increase.

These advanced systems even calculate an “effective minimum achievable carbon footprint,” showing the optimal point where emissions reduction meets cost efficiency. This approach transforms sustainability from a moral goal into a quantifiable performance parameter.

Cost vs. Carbon Trade-Off Curve: Shows how formulation optimization balances cost efficiency with carbon reduction targets.

By simulating multiple ingredient and sourcing scenarios, pet food companies can stay agile amid fluctuating prices and evolving sustainability expectations—turning environmental responsibility into an operational advantage.

Beyond the Formula: Energy and Supply Chain Efficiency

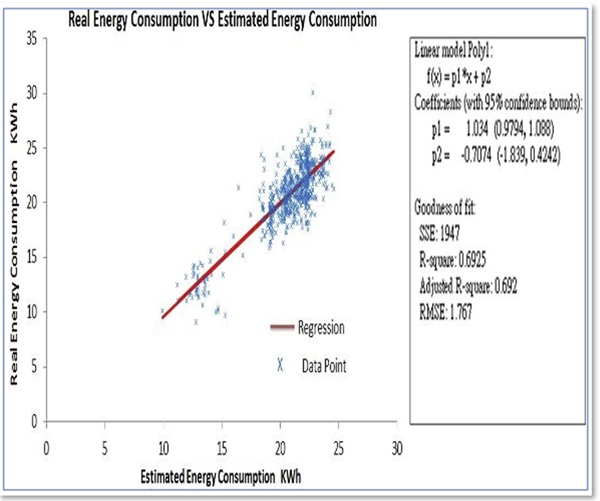

While ingredient choice drives most of a recipe’s footprint, the production process itself holds additional opportunities. Datacor’s collaboration with the Carbon Trust revealed that formulation can directly influence mill energy usage—and therefore total plant emissions.

Some ingredients demand more energy for grinding, extrusion, or mixing. By integrating energy consumption coefficients into optimization algorithms, manufacturers can formulate recipes that minimize energy use while maintaining nutrition and cost targets.

Energy-Use Regression Graph: Demonstrates the correlation between ingredient selection and mill energy consumption.

This holistic perspective—linking formulation, manufacturing, and supply-chain transparency—creates a continuous improvement loop. Every formulation decision ripples forward through production, distribution, and reporting, reinforcing measurable sustainability gains.

From Insight to Action

For companies ready to operationalize sustainability, Datacor recommends a clear, data-driven framework:

1. Understand your current situation. Use formulation and LCA data to establish environmental baselines.

2. Work with suppliers. Improve ingredient transparency and collaborate on data accuracy.

3. Assess reduction strategies. Apply multi-objective optimization to model trade-offs and identify cost-effective reductions.

4. Form an action plan. Set measurable targets, monitor progress, and evolve formulations as markets and materials change.

Four-step framework: Understand → Work → Assess → Plan, guiding manufacturers toward measurable sustainability goals.

This process turns sustainability from a broad aspiration into a repeatable operational practice—powered by data and delivered through digital tools.

Leading the Next Phase of Sustainable Pet Food

The next phase of growth in the pet food industry will be defined by how well manufacturers balance performance, profitability, and planet. Formulation sits at the heart of that balance, enabling innovation that benefits both business and the environment.

Datacor’s advanced formulation technology equips manufacturers to model, measure, and manage sustainability—transforming complex data into actionable insights that support long-term growth and global stewardship.

Learn how Datacor empowers pet food manufacturers to balance performance, profitability, and sustainability.

👉 Explore Datacor Pet Food Solutions

Or download the Advancing Sustainability in Pet Food Production eBook

Source:

1. FAO – FAOSTAT Analytical Brief 50 - 2020 figures

2. University of Edinburgh/PET Industry – Sep 2023

3. UK Petfood study 2024