Brand Insights from Kemin

Food safety for pet food is often viewed as minimizing the risks posed by pathogens, such as Salmonella. However, food safety encompasses more than managing recall risk. Pet food manufacturers invest significant resources into producing quality, nutritious, and safe pet food, so addressing microbial risks throughout the value chain is critical to a robust food safety program.

Managing Inherent Safety & Quality Risks

Microbial hazards not only threaten pet safety but also create public health risks due to the potential for direct human contact with pet food. To protect their business and brand from risks related to pathogen contamination, pet food manufacturers should implement microbial management strategies throughout the value chain, including:

- Implementing Good Manufacturing Practices (GMPs) and Hazard Analysis and Critical Control Points (HACCP) programs

- Providing ongoing training to employees on quality, food safety and hygiene practices

- Developing regular testing plans on finished products

- Maintaining a clean and hygienic production and packaging environment

- Sourcing quality raw materials from reputable suppliers and conducting supplier audits

Implementation of these steps is necessary to ensure the safety and quality of pet food and to mitigate recall risks. However, understanding microbial challenges in raw materials, their impact to quality and how to effectively manage them is also vital to maintain freshness, shelf-life and palatability of pet food.

Protecting Your Quality and Investment

Ensuring the safety and quality of pet food is a challenging and complicated process for pet food manufacturers and renderers alike. Variability in raw materials, complex supply chains, and various product formats and processes can lead to oxidative deterioration and microbial contamination in both ingredients and the pet food itself.

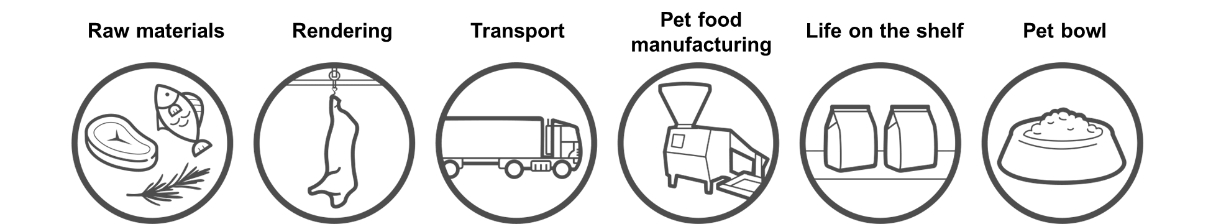

Antioxidants are commonly used to manage quality, improve shelf-life, and minimize impact to palatability due to oxidation. However, antioxidants do not help with microbial issues. Managing microbial risks through the value chain (Figure 1) can be just as important as controlling oxidation and, in some situations, can help support the effectiveness of the antioxidant.

Microbial impacts to pet food begin as early as the initial raw material processing, like when animals are first harvested for proteins and fats that will become components of a pet food diet. At this early stage, high moisture levels, presence of endogenous bacteria and enzymes and elevated temperatures can lead to rapid microbial growth, hydrolysis of fats and breakdown of proteins.

Hydrolysis of triglycerides results in elevated free fatty acid (FFA) levels in rendered fats and protein meals, which can impact pet food in two ways – reduced palatability and increased rate of oxidation. It is well known that elevated FFAs can have an undesirable impact on palatability of pet food. Additionally, FFAs are generally more prone to oxidation than trigylcerides1, and thus can reduce shelf-life of rendered fats, protein meals and ultimately finished pet food.

The breakdown of proteins can happen in both rendered raw materials and fresh or frozen meats. Protease enzymes hydrolyze proteins into peptides and amino acids, and amino acids can be further broken down into biogenic amines (BA)[AH1]. In low concentrations, BAs can play an important role in many physiological functions within the body. However, at high concentrations BAs have been shown to negatively impact palatability in both cat and dog food2,3 and may pose risks to animal health.4,5,6

Figure1: Pet Food Value Chain

An important first step in your food safety plan is to address the microbial quality concerns as early as possible in the process to minimize the downstream impacts on freshness, safety and quality. Using freshness control treatments like ALLINSUR™[AH2] and RENTERRA™[AH3] can help limit FFAs and control biogenic amine formation in raw materials thereby helping to ensure pet food is safe, high quality, fresh, and nutritious. CLICK HERE to learn more about Food Safety Solutions from Kemin[AH4]

References:

- Theodore P. Labuza & L. R. Dugan Jr. (1971) Kinetics of lipid oxidation in foods, C R C Critical Reviews in Food Technology, 2:3, 355-405, DOI: 10.1080/10408397109527127

- Kemin Source Document TPAS-22-2326

- Kemin Source Document US21F276

- Esposito F, Montuori P, Schettino M, Velotto S, Stasi T, Romano R, Cirillo T. Level of Biogenic Amines in Red and White Wines, Dietary Exposure, and Histamine-Mediated Symptoms upon Wine Ingestion. Molecules. 2019 Oct 8;24(19):3629. doi: 10.3390/molecules24193629. PMID: 31597389; PMCID: PMC6804232.

- Ruiz-Capillas C. and Herrero A.M. (2019). Impact of biogenic amines on food quality and safety. Foods. 8: 1-16.

- Ten Brink B., Damink C., Joosten H.M.L.J., Huis in’t Veld J.H.J. (1990). Occurrence and formation of biologically active amines in foods. International Journal of Food Microbiology. 11: 73-84.

[AH1]https://www.kemin.com/na/en-us/blog/petfood-rendering/pet-food-quality--understanding-biogenic-amines?utm_source=pet_food_industry&utm_medium=online_article&utm_campaign=food_safety_native_article&utm_term=food_safety&utm_content=april24_native_article&utm_bu=kn

[AH2]https://www.kemin.com/na/en-us/markets/petfood-rendering/products/allinsur?utm_source=pet_food_industry&utm_medium=online_article&utm_campaign=food_safety_native_article&utm_term=food_safety&utm_content=april24_native_article&utm_bu=kn