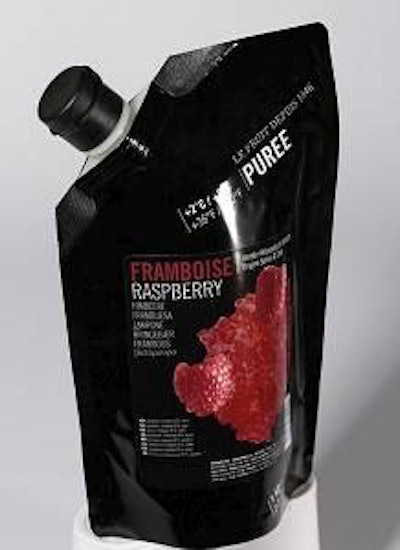

Ampac offers the AseptiPouch, a packaging\nformat for cold aseptic applications. The\nAseptiPouch is a pre-made stand-up pouch with a unique fitment. Engineered for\nprocessing on an Astepo aseptic filling machine, the pouches are gamma\nirradiated (sterilized) and shipped for the filling process. The fitment spout has a flip top cap that is fully removed prior to filling and\nimmediately reclosed after filling. The AseptiPouch system competes in distinct\ncontrast to alternative FFS aseptic packaging systems that require the laminate\nweb to be immersed in a peroxide bath prior to forming the now sterilized film\ninto a pouch.", "Available\nin three sizes (200, 500, and 1000 grams) and manufactured at Ampac’s Kirchberg,\nSwitzerland Manufacturing Center of Excellence, this process offers customers an\naseptic solution with multiple advantages for food quality, food taste and\nappearance, as fewer preservatives are used and nutritional vitamins are\nretained. The filling of low acid\nproducts is also now possible. ", "Further\nadvantages for aseptic filling for the AseptiPouch are cost savings to the\ncustomer. While hot fill and retort is water and energy intense, the cold\naseptic filling uses less water and energy/heat. With today’s sustainability\nfocus and awareness to environmental production, this provides an important\ncost savings, according to Ampac. Products that can be filled aseptically include beverages, soups,\nsauces, liquid foods, dairy products and desserts.", "