Maximizing profit margins and avoiding misbranding means knowing just what goes into your petfood and treat products. Accurate measurement and precise adherence to levels of moisture, fat, proteins and other key nutrients is more important than ever. That means ideal process control technology should be able to:

-

Operate in harsh industrial environments;

-

Take measurements in real-time;

-

Have little to no human intervention for operation and calibration; and

-

Provide instant, accurate data.

The speed of light

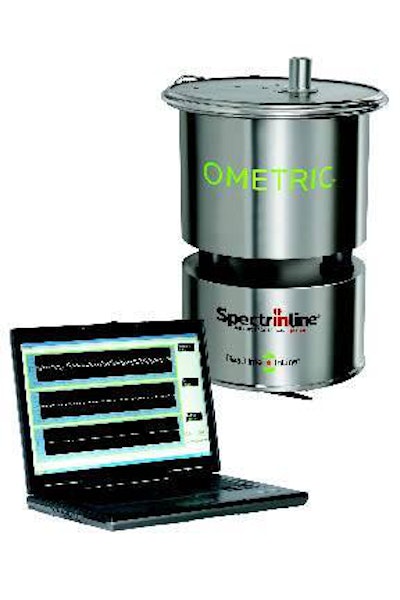

Ometric provides manufacturing and process spectroscopy solutions for a broad range of industry categories, including petfood manufacturers, that share a need for real-time, in-line continuous process control and final product testing. The company has recently unveiled its SpectrInLine Process Control Suite, which is installed directly in the process line. This technology allows manufacturers to measure, monitor and control their manufacturing process and can be applied to:

-

Pre and post extrusion;

-

Pre and post drying;

-

Pre and post enrobing;

-

Real-time moisture control; and

-

Fat and protein control and monitoring.

The technology also works for a variety of shapes and sizes of feline and canine food and the results are not affected by sample color.

"Due to significant limitations associated with sample testing, modern manufacturers can no longer afford to rely on traditional methods. Large amounts of out of spec product can be produced waiting for lab results," says Walter Alessandrini, chairman and CEO of Ometric Corp. "Our revolutionary technology is specifically designed to address manufacturing process control concerns by providing real-time benefits that ensure fewer product recalls, less waste, minimized liability and an increased savings on resources."

Ometric's technology allows users to view production runs by their choice of dates, shifts, product lines and plants. Results are shown in a graphical format and are designed for easy interpretation. Information may also be shared with others, allowing managers to analyze current and historical data and adjust their processes as needed to ensure proper quality and final product formulation.

According to the company, SpectrInLine Processware is a complete system that utilizes application specific multivariate optical computing to provide continuous spectroscopy in real-time for industrial processes. The SpectrInLine process control suite's web-based interface gives users access to critical manufacturing information from any computer, PDA or smart phone with Internet access.

Control your quality

CSB-System now offers a method that ensures constant and reliable monitoring of your entire manufacturing process. Quality Management is a fully integrated feature of the business process solution, according to the company. It fully complies with all industry standards for HACCP, ISO 9001:2000 and the International Food Standard. The QM and HACCP module is completely integrated into the materials management of an existing CSB system to ensure that all tests that may be done during production can be recorded in process (e.g., right at receiving). The Quality Management arrangement also makes certain that the proper action is initiated instantly as the results are processed. In extended options of the system, you can use the results to adjust your pet product recipes based on raw material potential (meat protein, fat, sugar content).

Detective work

The InAlyzer system using the Thermo Scientific Guided Microwave Spectrometer (GMS) is an in-line, multi-constituent analyzer that monitors any process flowing through a pipeline. The GMS uses very low-powered microwave energy at hundreds of specific frequencies to analyze the physical and chemical properties of a sample. GMS is best at determining multiple constituent concentrations of a process with varying particle sizes. The system includes the chamber, electronics control module, industrial PC and PC-based software for developing calibrations and SQL database for key data and configuring the InAlyzer. It is available in both online process and at-line laboratory configurations.

InAlyzer can measure water activity in petfood in real-time and in-line, a very important factor with regard to spoilage and shelf life. Unlike other analyzers, its simple design contains no moving parts or optical components that require routine maintenance, resulting in extremely low long-term cost of ownership, says Aaron Chabino, project manager at ScanAmerican Corp, which distributes the InAlyzer in North America. Advantages of GMS include:

-

Analyzes multiphase products such as slurries, dough, liquids and larger particle size products;

-

Analyzes multiple components;

-

Measurement is representative of the bulk product even for heterogeneous materials, as it is not a surface measurement; and

-

Results are not affected by the sample color.

Analytical tests that were once carried out in the lab can now become part of the online inspection process, which reduces the risk of producing out-of-specification product. The Thermo Scientific Spectra-Quad online moisture and constituent analyzer provides continuous, accurate, real-time information about the concentration of key product components. According to Darrel T. Butler, GMS specialist and key account manager for Thermo Fisher Scientific, the Spectra-Quad detects not only melamine present in petfood but protein independently as well.

The Spectra-Quad uses a measurement technique based on near infrared (NIR) light absorption. It is a non-contact, nondestructive and non-hazardous method. Chemical bonds absorb NIR light at well-defined wavelengths. The absorption intensity at a given wavelength is proportional to the amount of the constituent in the material.

A quartz-halogen light source emits NIR light and the light from the source passes through a rotating filter wheel. The filters in the wheel allow only a narrow band of NIR wavelengths to pass through. The reference wavelength provides a baseline for the measurement of the sample. Some of the light is absorbed by the sample and the rest is reflected. The reflected light is collected and then focused onto a detector. The signal at the detector is processed to provide a reading that is proportional to the constituent concentration.

A full function operator interface permits easy access to all of the analyzer's setup and diagnostic functions. The display includes the product's name and its measured values, and can be configured to function in several languages. The Spectra-Quad is available with a wide range of environmental options, which enables the analyzer to perform in virtually any petfood or treat production situation, according to the company.

.png?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)