Proteine Resources, a Polish biotech company specializing in advanced mealworm-based protein technology, has developed what it said is the world's first scalable beef analog with a 1:1 nutritional profile to real beef, reducing production costs by up to 50%.

The company noted this innovation is designed for pet food manufacturers seeking cost-effective and sustainable alternatives to traditional meat ingredients, especially as concerns over environmental impact and pet allergies increase.

After five years of intensive research and development, Proteine Resources said it has implemented a network of modular, AI-driven mini-factories to achieve rapid scalability. The company has tripled production capacity at its facility near Krakow, Poland, and is building its first full-scale pilot factory in the region while expanding its R&D efforts.

Beef substitute for pet food

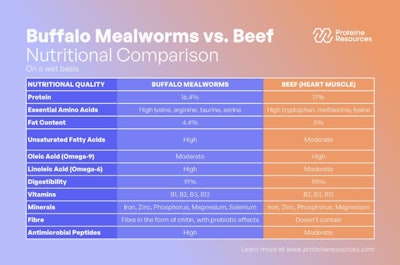

Proteine Resources said it is working on a beef substitute for pet food -- designed as a high-quality, stable 1:1 beef meat replacement, with 70% protein in dry granule form (16.4% in wet form versus 17% in beef). Using buffalo worm protein, the company said the product provides all essential amino acids, iron, vitamin B12, and omega-6 and omega-9 fatty acids, without chemicals and GMOs. It is also hypoallergenic and prebiotic, supporting animal gut health. The company said the product offers an attractive taste, aromatic scent and customizable texture thanks to advanced structural technology.

100% beef analog based on entoproteins

Proteine Resources said it runs its entire insect breeding cycle in the dark, cutting the production time to just four weeks, and automating facilities. The company explained this slashes resource consumption and lowers greenhouse emissions compared to other insect or plant-based proteins. The company also noted this breakthrough stems from years of intensive R&D and delivers a fully functional 100% beef analog based on entoproteins — not mycoproteins.

Proteine Resources envisions over 40 potential applications of its technology — both for humans and animals — but chose the pet food market first due to lower regulatory barriers, and a fast-growing market facing high raw material costs and widespread pet health issues. Studies show that nearly one in three dogs and 15% of cats suffer from food allergies, 2 with beef causing 34% of cases in dogs, and chicken affecting 15%. The company's internal tests are promising in terms of reducing this common issue.

"We went beyond a simple beef analog to add real functional value," said Konrad Włodarczyk, co-founder and co-CEO of Proteine Resources. "By replacing just 20% of traditional meat with our analog, we can eliminate allergies in many animals. Consumers still get the familiar beef or lamb product, only healthier, while pet food producers benefit from higher margins and lower costs." Bartłomiej Roszkowski and Konrad Włodarczyk note buffalo worm protein is up to 25% cheaper than beef.Proteine Resources

Bartłomiej Roszkowski and Konrad Włodarczyk note buffalo worm protein is up to 25% cheaper than beef.Proteine Resources

A new era in pet food production

Strong demand for the company's products has led to it tripling production capacity at its Masłomiąca facility near Krakow. With the pet wellness market in the U.S., Canada and EU valued at €93 billion (US$100 billion) — and expected rapid growth driven by the humanization of animals — the company said it is set to transform pet nutrition.

Proteine Resources has raised €1.82 million (US$1.9 million), including €1.36 million from VC funds Bitspiration Booster and SMOK Ventures, to support these operational breakthroughs. The company aims to secure its first contracts soon and sign off-take agreements worth €3 million by mid-2026, positioning its breakthrough technology as a viable solution for pet food manufacturers seeking to enhance nutritional profiles and reduce costs while meeting growing market demands.

"Biotech/deeptech projects require time and significant investment in development and commercialization," said Bartłomiej Roszkowski, co-CEO of Protein Resources. "Last year’s round accelerated our growth, enabling us to achieve over 80% of our goals quickly. We aim for the next round to propel us even further."

Proteine Resources is building its first full-scale pilot factory in Poland and expanding R&D in Krakow. With five letters of intent signed and declared demand for annual production, the company aims to sign its first contracts soon and secure €3 million in off-take agreements by mid-2026.

Adapted from a press release.