Ensuring delivery of your pet food’s brand promise of quality is vital for consumer assurance. While there are many aspects used to assess quality, the expectation is that the food is safe when consumed and it is what it claims to be on the label. By fully understanding vitamins, vitamin product forms, their application in pet food formulation and vitamin premix quality, manufacturers can take the right steps to ensure the correct and safe supplementation of their products, which in turn helps to protect brand equity, a company’s most valuable asset.

What do vitamins have to do with consumer assurance?

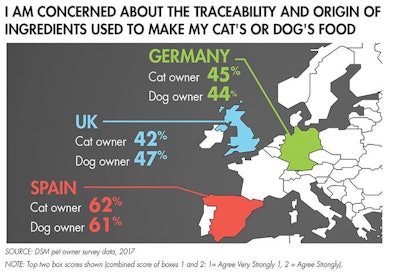

Food quality is high on the consumer’s agenda, not only for themselves but also for their animal companions due to highly publicized food fraud scandals, increased nutritional health awareness and pet humanization. DSM’s pet owner survey data (2017) demonstrated that owners are concerned about the traceability and origin of ingredients used to make their pets food (see Figure1). It therefore makes sense to learn more about your ingredient supply chain to fulfill the consumer need for ingredient sourcing transparency.

FIGURE 1: A significant portion of dog and cat owners in Europe say they’re concerned about the ingredients used in their pets’ food.

As an additional consideration, pet parents now seek foods that reflect current human food, nutrition and health trends. This has increased the complexity of pet food recipes as novel and humanized ingredients are required to meet the demands of increasingly discerning pet owners. Management of complex ingredient supply chains to source these new ingredients, however, is resource intensive and often difficult to navigate.

One ingredient that does remain constant in pet food recipes is the vitamin premix. It is often overlooked as one simple commodity ingredient, but the premix is a complex blend of many other ingredients and should receive individual attention to ensure it is fit for its relevant purpose, ensuring safe pet food supplementation.

Proper dosing of vitamins and pet food safety

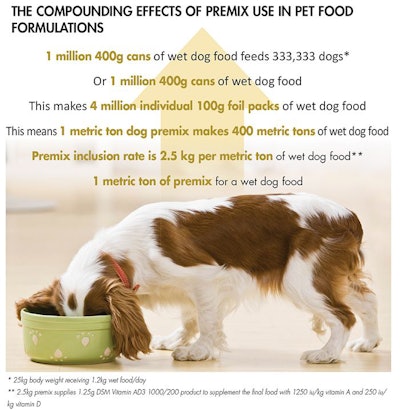

Vitamins are only needed in micro amounts by the animal. Individually weighing and adding vitamins separately during the food production process carries a high risk. If done incorrectly, nutritional quality or even food safety at the point of consumption will be compromised and can have far-reaching consequences (see Figure 2). It is therefore essential that they are accurately added to the food. By blending the small amounts of vitamins or other micronutrients required onto a carrier to create one ingredient, the premix, they can be safely added to and distributed uniformly throughout the final pet food product. Proactively managing the vitamin sources used in your premix and final premix formulation quality with your supplier is one way to help mitigate the risk of a complex ingredient harming your pet food brand.

FIGURE 2: Adding the small amount of vitamins required in pet food via a high-quality premix ensures accurate vitamin addition distribution throughout the food, which in turn guarantees nutritional adequacy and safety for the end user. | Pictrough, BigStockPhoto.com

For commercially produced pet nutrition products, the vitamins used within them must be safely produced and formulated into specialized forms. These forms must be selected and applied consistently throughout the supply and production chain, from storage and handling to their proper inclusion in a premix, considering the pet food type, production process and finished food product storage.

Developing a quality premix: How does your vitamin premix affect the quality of pet foods?

Many factors need to be considered when designing a vitamin premix specification and selecting vitamin forms to deliver the desired nutrient levels in the pet food at the point of consumption. These include the species to be fed, label or functionality claims that must be fulfilled and the type of product requiring fortification. Expected vitamin loss during production and storage should also be reflected in the specification, with vitamin activity overages calculated accordingly.

The correct premix dilution rate with a suitable carrier is required to ensure premix flowability, ease of handling and final weighment at the food production plant. The carrier also supports proper distribution of the vitamin forms within the food mix. The quality of carrier used as the premix base is just as important as the vitamin forms used. Carriers help bridge the often-unavoidable differences in micro-ingredient product form size, shape and density. Organic carriers such as rice hulls, pea fiber, maize and wheat middlings provide a large surface area or pockets for the nutrient ingredient forms to adhere to, while calcium carbonate increases bulk density of the premix and improves flowability.

A combination of inorganic and organic carriers is often used to help improve the homogeneity of micro-ingredient distribution within the premix. Carrier ratios can be modified to manipulate premix bulk density to specific handling needs if necessary. Another important consideration is the final pet food’s marketing claims.

Integrated supply chain and traceability

Pet retail products range from concentrated dietary supplements to pet foods designed to deliver 100 percent of an animal’s daily nutritional needs. Due to this complexity, and the safety concerns associated with these types of retail products, it makes sense that ingredient traceability is vital. A trusted supply chain is therefore needed. A food safety program in line with food safety standards is the basis for this, starting with strict ingredient vendor qualification and management processes. Robust and integrated documentation, goods receipt and warehouse management systems are required, which should be open to interrogation.

The process of manufacturing bioactive micro-nutrients and blends of micro ingredients is complex from a quality assurance perspective. Through involvement in all three steps of the nutritional ingredient chain — the production of pure active ingredients, their incorporation into sophisticated forms and the provision of tailored premixes — integrated premix and micro-ingredient producers offer unrivalled traceability to the pet food industry. Traceability, supported by rapid global track-and-trace systems, provides an additional assurance of safety.

Godfrey is the technical marketing manager, companion animals at DSM Nutritional Products UK.

Vitamins as pet food ingredients: