A wide range of microbes can potentially contaminate pet foods and treats, so manufacturers use a variety of methods to preserve their products. Radiation, for example, can inactivate harmful microorganisms without heat or chemical preservatives, particularly those with higher moisture content that are more prone to spoilage. By disrupting the DNA of bacteria and other pathogens, radiation can reduce the risk of contamination while maintaining the nutritional and sensory qualities of the food. However, radiation must be applied at appropriate doses to avoid degrading the nutrition or structure of the pet food.

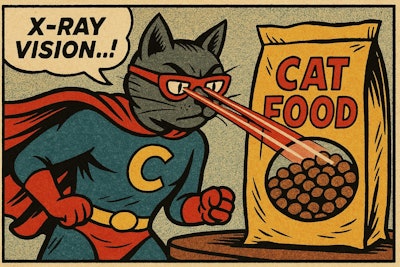

To determine the ideal dose of radiation for semi-moist pet foods, researchers exposed samples to doses of 0, 2.5, 5, and 10 kiloGrays (kGy) of x-ray radiation. The scientists then analyzed the pet food’s microbial load, nutrient content and physical properties over a 60-day refrigerated storage period. Results showed that a 10 kGy dose fully sterilized bacterial pathogens and suppressed regrowth for the entire storage duration. However, samples treated at this level also exhibited marked changes in moisture content, protein degradation, water activity, pH and color values.

Irradiation at 5 kGy emerged as the most balanced treatment, significantly reducing pathogenic bacteria while limiting adverse effects on nutritional and physicochemical qualities. This dose maintained better retention of protein and moisture content and reduced the rate of lipid oxidation and protein breakdown during storage, compared to higher irradiation levels.

“Considering all results, we conclude that about 5 kGy X-ray irradiation could prevent microbial activity while maintaining the maximum losses of nutritional and physicochemical properties of semi-moist pet foods,” the researchers wrote in the journal Animal Feed Science and Technology.

Challenges to the acceptance of x-rays for pet food preservation

X-ray irradiation, a non-thermal technology, may offer unique advantages over more established ionizing radiation methods such as electron beam and gamma ray, the study authors wrote. X-rays penetrate dense and packaged materials more effectively, enabling uniform sterilization without compromising surface texture. These characteristics could make X-ray technology especially suitable for pre-packaged semi-moist pet food products, potentially reducing risks associated with post-processing contamination.

However, regulatory and consumer perception challenges remain to the use of x-rays, they noted. The United States Food and Drug Administration permits irradiation of specific feed ingredients under controlled conditions, but the technology is less widely accepted in other markets. In the European Union, use is tightly restricted, with some member states prohibiting it entirely. Additionally, the requirement to label irradiated products with the Radura symbol has fueled consumer concerns due to misconceptions about radiation and food safety.

With growing demand for safer, longer-lasting pet food products, and increasing scrutiny over pathogen control in refrigerated items, X-ray irradiation could represent a viable processing innovation for certain segments of the pet food industry, especially semi-moist formats. Further research may help refine dose thresholds and build industry-specific guidelines for broader adoption, while laying the foundation for consumer acceptance.