Sponsored content by Coperion K-Tron

Global wet pet food sales have seen a recent increase in growth due to an increased trend in cat and small dog ownership by millennials, gen-Z-ers and baby boomers. For example, smaller dogs can be fed more affordably with wet food than large dogs. In addition, cat ownership has risen globally, with significantly increased ownership in the Asian and Pan-Pacific markets. The added pet food trends of humanization of pet food (including the use of plant proteins), grain free, and customized premium ingredient recipes all present additional challenges for wet pet food producers.

The accurate and automated addition of dry ingredients including majors, minors and micros to the wet pet food process is critical to maintaining low overall cost of high value ingredients, improved product quality, and overall process efficiency. In addition, automated material handling methods such as pneumatic transfer and automated dispensing eliminate typically manual steps and greatly improve overall pet food product safety.

Wet Food Production

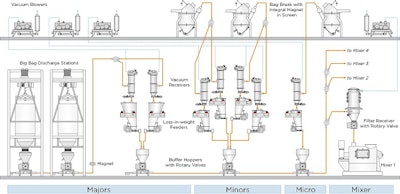

Dry ingredient addition to the wet pet food process typically occurs at the beginning stages, prior to the mixing and grinding steps. Majors, minors and micros can be introduced from a variety of sources, including boxes or drums, bag break stations or bulk bag/super sack unloaders. Upon discharge from these methods they are typically conveyed over to a high accuracy batching method, either via loss-in-weight or gain-in-weight for accurate ingredient proportioning as shown in Figure 1.

Figure 1: Sample process diagram for wet pet food production.

The correct and automated proportioning of the ingredients ensures that the product quality is maintained, while adding extra flexibility to the line for various recipes. From this batching method, the proportioned ingredients are then pneumatically transferred to a receiver with discharge directly to the mixer or mixers below. After mixing and grinding the product is usually cooked with steam (also known as the “kill step”)

|

|

Figure 2: Coperion K-Tron Side Access Filter Receiver |

to ensure product safety. Subsequent to the cooking step, the sauce or jelly is added to the product, in addition to any additional ingredients such as vegetables. Final steps include canning, sterilization and packing. It is important to note that production of the gravy or sauce can also include the dry ingredient dispensing. Precise and automated metering of these ingredients is often also done by the transfer and batching methods outlined below.

Ingredient Transfer: What Method is Best?

The arrival and transfer of major, minor and micro ingredients to a wet pet food plant can include a number of different types of conveying systems. The mode of transfer of ingredients is dependent upon a wide variety of process parameters, including material characteristics, distance to be transferred, required rate of transfer, and the type of container in which the ingredient is originally received. PLC systems featuring recipe control for multiple ingredients can easily be integrated into this transfer system, in order to allow maximum flexibility for the system.

Selecting the Right Conveying Technology

Depending upon the volumes required, possible sources of ingredient delivery include boxes, sacks, bulk bags or super sacks. Pneumatic conveying systems can be used to transfer these ingredients in all steps of the process, utilizing either positive or negative pressure dilute phase conveying. Positive pressure conveying systems are typically used to transport bulk materials over long distances and at high throughputs. Applications which involve pressure conveying often include loading and unloading of large volume vessels such as bulk bags

Conversely, vacuum (negative pressure) systems are often used for lower volumes and shorter distances. One of the advantages of vacuum systems is the inward suction created by the vacuum blower and reduction of any outward leakage of dust. This is one of the reasons why vacuum systems are often used in higher sanitary or dust containment applications. Another advantage of vacuum systems is the simple design for multiple pickup points. It should be noted, however, that the distances and throughputs possible with a vacuum system are limited due to the finite level of vacuum that can be generated.

A continuous vacuum system utilizes a continuous vacuum source and a filter receiver (Figure 2) with a rotary valve below to maintain vacuum within the receiver and constant output at the same time. In a vacuum sequencing system the vacuum receiver is fitted with a discharge valve. When closed, the system transfers the material until a preset time or fill level is reached. Once the receiver is full, or the time elapsed, the vacuum is broken, and the discharge valve on the receiver opens and discharges the material. In the case of the sequencing receivers, a pulse of air is blown through the filters within the receiver during this discharge, in order to avoid material build up on the filter media and optimize conveying efficiency. The process is sequenced and repeated until the specified amount is delivered to the process below, such as the mixers shown in Figure 1.

It is important to note that vacuum sequencing systems typically allow for more versatility in product pickup and destinations, and also can often utilize a single vacuum source for several receivers, depending upon the demands of the downstream process.

Batching Systems

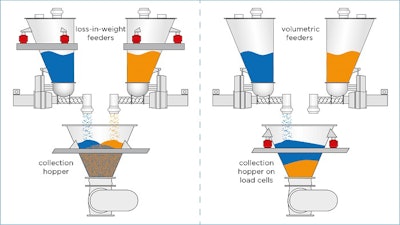

After transfer from the material source, the ingredients are usually delivered to the batching station. This station can include volumetric metering devices, such as screw feeders or valves, which deliver the product to a hopper on load cells. This method is called Gain-in-Weight (GIW) batching. Alternatively, the station can include gravimetric feeding devices, such as screw or vibratory feeders, mounted on load cells or scales, which deliver the product to the process by means of Loss-in-Weight (LIW) feeding. As outlined below, in some cases where small amounts of micro ingredients are required for a total overall batch, both methods can be combined: LIW feeders for the micros and minors, and GIW batchers for the major ingredients.

Gain-in-Weight Batching

|

|

Figure 3: Coperion K-Tron Scale Hopper with Aeropass Valve at top |

In GIW batching volumetric metering devices sequentially feed multiple ingredients into a collection hopper mounted on load cells. Each feeder delivers approximately 90% of the ingredient weight at high speed, slowing down towards the end of the cycle to deliver the last 10% at a reduced rate to ensure higher accuracy. The GIW controller monitors the weight of each ingredient and signals each volumetric feeder to start, increase or reduce speed, or stop accordingly. Once all the ingredients have been delivered, the batch is complete and the mixture is discharged into the process below. It should be noted that this type of batching method is sequential for each ingredient, and therefore generally results in a longer overall batching time than with LIW batching (outlined below) if the number of ingredients is high.

GIW Batch Weighing with Scale Hoppers

When major ingredient batching requires a single ingredient to be delivered to multiple stations or multiple ingredients delivered to a single destination, scale hoppers with specialty Aeropass™ valves mounted above the scale hopper can be used. After the fluidized material is discharged from a source such as a silo or bulk bag, it will typically drop through a rotary valve, through a sifter (if required), and is then metered into the conveying line by another rotary valve. Once in the convey line, it is then transported to the Aeropass valve, located above a scale hopper, as shown in Figure 3. Scale hoppers are receiving hoppers suspended on load cells for ingredient batch weighing. The material resides in the scale hopper until the precise weight and/or combination of materials is achieved. With the scale weighing system, weigh accuracies of +/- 0.5% of the full scale capacity can be expected. Once the desired weight has been achieved, the mixer then calls for material, a butterfly valve opens and the material in the scale hopper is discharged.

Loss-in-Weight Batching

|

|

Figure 4: A Coperion K-Tron gain-in-weight batching system in a food application |

LIW batching utilizing high accuracy screw feeders, such as those shown in Figure 4, provides a significant accuracy and process time advantage over traditional GIW batch techniques. LIW batching is used when the accuracy of individual ingredient weights in the completed batch is critical or when the batch cycle times need to be very short. Gravimetric feeders operating in batch mode simultaneously feed multiple ingredients into a collection hopper. Adjustment of the delivery speed (on/off, fast/slow) lies with the LIW feeder controls and the smaller weighing systems deliver highly accurate batches for each ingredient. Once all the ingredients have been delivered, the batch is complete and the mixture is delivered to the process below. Since all ingredients are being delivered at the same time, the overall batch time as well as further processing times downstream are greatly reduced. This method of batching is often used for high value ingredients due to the highly accurate requirement of their weight in the mix as well as their ingredient cost.

As shown in Figure 5, in the LIW batch process the actual amount of product which leaves the feeder is determined by measuring the difference, or loss in weight. As with GIW batching, the first 90% of the batch weight (as determined by the pre-programmed recipe) is fed at a fast rate by the feed screws. The last 10% is fed in a slower “dribble” mode to ensure an accurate batch weight, reaching accuracies of ± 0.1% of the desired setpoint. In this example, the Coperion K-Tron Control Module (KCM) uses the LIW Batcher control software to regulate the delivery speed (on/off, fast/slow) and also offers the possibility to quickly change batch setpoints based on the packaging requirements for each product.

Figure 5: Loss-in-weight batching (left) vs. gain-in-weight batching (right)

Why LIW Feeders Are Ideal for Batching

Coperion K-Tron’s gravimetric feeders feature digital load cells to constantly measure the weight of the ingredient being delivered to the process below. LIW feeding affords broad material handling capability and thus excels in feeding a wide range of materials from low to high rates.

All Coperion K-Tron LIW feeders use patented Smart Force Transducer (SFT) digital load cell technology. This technology has 1 part in 8,000,000 resolution in 20 ms and includes vibration filtration and temperature compensation which allow the feeder to be controlled on a second to second basis with unprecedented performance levels.

For additional information and application information on extrusion, feeding and material handling for all pet food and pet treat processes, see www.coperion.com/petfood.