The final test of a pet food’s acceptability comes when it’s poured into the bowl of a waiting pet. If the pet doesn’t like the food, it’s a given that the pet’s owner will immediately switch to something else. In this day and age, when consumers are more in tune to their pets’ needs and wants than ever, it’s important for pet food manufacturers to ensure that their product is as palatable as possible.

The latest palatability analysis tools are more sophisticated than ever, working with each other to give manufacturers the broadest look possible at their products. AFB International has been using electronic nose and electronic tongue technology (ENT) to help analyze the overall smell and taste of pet foods since 2007, and in November 2014, the company upgraded its electronic nose technology to the latest generation of instrument. These tools, according to the company, complement other analytical techniques to provide a more in-depth look at palatability profiles.

Courtesy AFB International

Electronic nose and electronic tongue technologies, in conjunction with other analytical tools, allow for a more in-depth palatability profile, according to AFB.

“In the human food industry, you have human sensory panels that can tell you about different descriptors when they taste and smell the food,” said Punyatoya Mohapatra, analytical chemistry manager for AFB International. “[With ENT] we want to understand the aroma and taste profiles of our products. Palatability tests measure performance based on various methods. However, palatability tests are unable to provide flavor descriptors to pet owners who make the buying decisions.” ENT allows AFB to translate the results of such questions into language they can then use to help consumers understand their pets’ food.

The technology does have its limitations, which is why it’s one analytical tool of many used to get the full palatability picture, said Mohapatra. “For me, it’s a qualitative tool,” she said. “It’s a technology to complement other analytical tools and it’s nice to have, because a lot of the time many of our customers are not aware of the details of the various analytical tools that are out there. These technologies are constantly evolving.” Most of the limitations of ENT, according to Mohapatra, are with the types of samples the technology can handle. Complex flavors with multiple compounds can present challenges from an instrument standpoint, because ENT tools are very sensitive, and samples must be stable enough to be accurately analyzed.

Another challenge is in the origins of the technology. “The instruments were designed and developed keeping in mind the human food industry,” said Mohapatra. “So as the technology has been going more broadly into other industries, how we can apply it to the pet food industry is of course a big challenge. Because in the human food industry, these instruments have been used to supplement the human sensory panels, and they have accountability from human beings.”

ENT shines as a complementary tool for in-depth palatability analysis, according to Mohapatra, and its limitations are offset by other analytical techniques. In addition, Mohapatra said the current challenges are where the possibilities for ENT advancement lay—technologies that can handle more complex or unstable compounds, the ability to better quantify the analysis, and even an eventual combination of the qualitative and quantitative instruments are all possibilities, she said.

Palatability technologies can also provide practical benefits that extend beyond taste, according to Kemin. The company’s patent-pending pH-adjustor palatant technology incorporates organic acids into specially designed palatability enhancers, resulting in the ability to strike a balance between acidification and palatability.

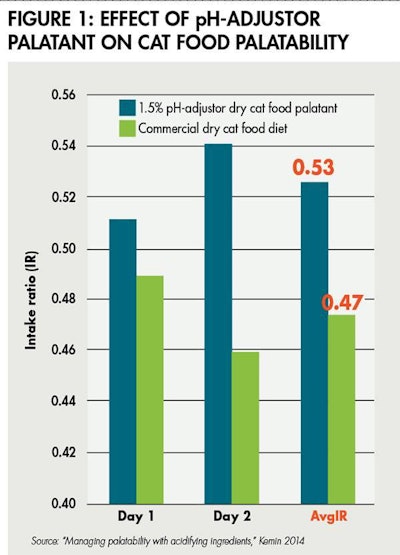

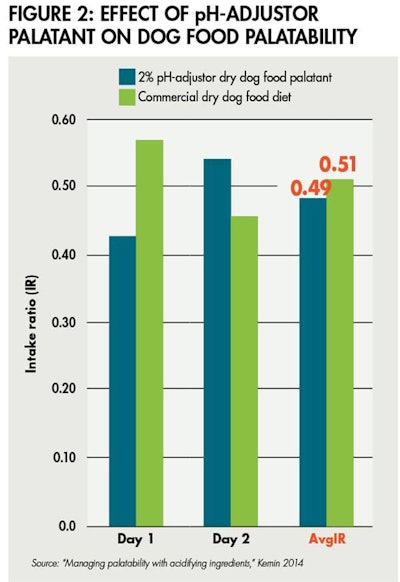

Kemin considered an extensive list of potential compounds that could serve as acidifiers for the pH-adjustor palatants. Screening was based on regulatory status and pH impact on model systems, as well as palatability testing with cats and dogs. Based on the screening results, Kemin researchers found three viable acids—fumaric acid (see Figures 1 and 2), succinic acid and sorbic acid—that offered the correct balance of performance requirements. “These three acids can be used singly or in combination,” said Lynn Deffenbaugh, global palatant product manager for Kemin. “In some cases they have a better efficacy in combination, but they are also quite effective when used alone. A wide range of pH-adjuster palatant products can be made with different combinations of these organic acids that are applicable to different pet food diets and palatability levels.”

To study the effects of its pH-adjustor technology on cat food, Kemin added 0.4% fumaric acid to a cat diet and then replaced the control palatant with a pH-adjustor palatant applied at 1.5%. According to Kemin’s results, cat palatability was parity to a commercial benchmark diet—the target for the pH-adjustor palatant diet.

Kemin also studied the effects of pH-palatants on dog food. At 0.4% fumaric acid and 2% pH-adjustor palatant, palatability was parity, showing that pH-adjustor palatants can be designed to maintain target palatability.

pH-adjustor palatants are available in a dry format and can be designed for different topical application levels. “Generally, a higher application rate is needed for higher palatability targets for both dogs and cats,” said Deffenbaugh. “pH-adjustor palatants that have met both acidification and palatability targets have been designed for application rates ranging from 1% to 2.5%.”

A secondary food safety benefit was discovered due to the inclusion of the acidifiers in the pH-adjustor technology. “The concept of acidification and the impact on antimicrobial growth is very well known; however, the biggest challenge is in maintaining overall palatability,” said Deffenbaugh. “Another challenge is even distribution of the organic acids, which is accomplished by using the palatant as a vehicle and utilizing existing equipment and process capabilities at the pet food manufacturer.”

Food safety is one of the largest concerns in the petfood industry, according to Deffenbaugh. “pH-adjustor technology provides an additional layer of food safety assurance in addition to what pet food manufacturers are already doing in the factory to deliver the highest quality pet food.” The added protection with pH-adjuster palatants also carries beyond the manufacturing plant through the distribution system and even when the pet food is in the consumer’s hands.

A key driver of pet food palatability technology is the human buying the food, because they’re the ones watching to make sure their pets are enjoying dinner. Diana Pet Food has honed in on this by testing “emotional palatability”—a phrase encompassing the owner-food-pet triangular relationship and acknowledging that palatability deals not only with pet-centered preferences, but also with the pet owners’ perception of their pets’ feeding satisfaction.

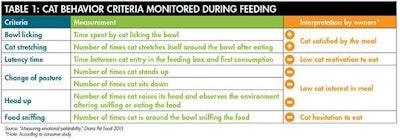

Using roughly 100 different dry cat foods, Diana Pet Food studied individual kinetics of consumption in Panelis, its center in palatability measurement, in order to put together pictures of each food’s emotional palatability. Components such as attractivity (e.g., the percentage of cats visiting feeding stations at the beginning of the test) and consumption per passage (e.g., the amount of food eaten during the first meal following preparation time) were monitored using video and other analysis, and a picture of emotional palatability began to emerge. From meal preparation (the first step in emotional palatability, according to Diana Pet Food) to during-meal behavior (see Table 1) through post-meal temperament, the cats were closely studied to determine their overall satisfaction with their meal—and, therefore, how that satisfaction (or lack thereof) would present to a human owner.

Diana’s study included analysis of various satisfaction-based criteria that pet owners would themselves monitor during their pet’s feeding, providing a measurement of those criteria and probable interpretation by owners.

“Meal time is increasingly considered by pet owners as a privileged moment to create emotional bonds with their animal,” said Diana Pet Food. “To make meal time a shared enjoyable moment, pet food manufacturers not only need to satisfy pets’ appetite, they also need this satisfaction to be clearly perceptible by the owner.”

From analysis to integration of industry concerns to the human element, palatability is an ever-changing, complex characteristic of pet food manufacturing. Utilizing and advancing technologies that can support palatability needs is the best way to ensure continued success in all these areas.

More on pet food palatability