Worm composting, or vermiculture, may reduce both waste disposal costs and environmental impacts, a rare win-win for ecology and economics. I saw industrial vermiculture in action a few years ago in Chile. I toured a rendering plant where the remnants of fish became salmon meal. Much of that meal would be exported as a pet food ingredient in the United States.

“We’re essentially a recycling plant,” Benjamin Izquierdo, commercial manager at salmon rendering facility Pesquera La Portada, told Petfood Industry during the tour.

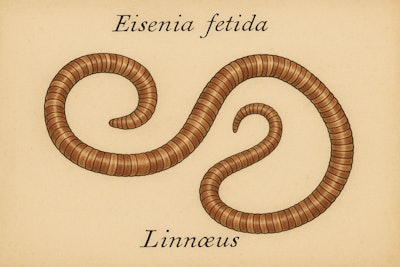

The liquid waste from the plant feeds their worm beds. The plant installed seven worm farms where tiger worms (Eisenia fetida) devour the processed liquid waste after it is sprayed into their beds. These beds act as natural filters to protect local watersheds while producing fertilizer that is used in local reforestation projects.

Worms may provide waste management for other ingredient suppliers and pet food makers. In an experiment, scientists tested the potential for unusable kibble to become worm food and subsequently soil fertilizer. Fermentation pre‑treatment proved to be essential to the successful vermicomposting of pet food industry waste.

“This work demonstrates that combining microbial pre-digestion with vermicomposting can upcycle pet food waste into valuable soil amendments, while supporting local circular bioeconomy and sustainable waste management,” the researchers wrote in the journal Waste Management.

Untreated kibble and wood fiber mixes led to 100% worm mortality, but with fermentation pretreatment, the red wiggler worms (Eisenia andrei) could consume up to 20 kilograms per week per square meter of worm farm. The researchers noted this is up to four times higher feeding rates than in earlier studies. The fermentation stage essentially softens or biologically predigests the feed–fiber mix, making it more amenable to worm ingestion and decomposition. Lower kibble incorporation (15%) generally improved worm attraction vs higher incorporation (30%).

The type of wood fiber used also affected the worm farm. Beech sawdust, as opposed spruce, resulted in better worm palatability, lower pH and higher quality finished composts. However, using commercial microbial inoculants versus collections of microbes taken from the surrounding environment resulted in similar final communities of microorganisms. Nor did the size of the container used.

Regardless of the variables, the final vermi-composts met French standards for organic amendment quality, including trace elements and pathogen absence.

How pet food makers and ingredient suppliers can start worm composting

Using the results of this study, here is a roadmap for integrating vermiculture into pet food and ingredient production facilities.

1. Waste stream audit and fractionation

- Identify and segregate waste streams containing high‑value or high‑nitrogen components (e.g. expired kibbles, scrap ingredients) and lignocellulosic/wood residues (e.g. wood shavings, sawdust, packaging cardboard).

- Characterize composition (moisture, C:N, ash, inhibitors) to decide blending ratios (e.g. 15% vs 30% kibble as in the experiment).

- Given the sensitivity observed, firms may want to pilot multiple fiber types (hardwood sawdust, softwood chips, wood pallets) to assess worm response and final product metrics.

2. Fermenter design and scale

- For an industrial operation, a modular system of fermenter “bins” may suffice, rather than expensive large reactors.

- Maintain micro‑aerobic conditions during the first 14 days (minimal mixing) followed by periodic aeration (manual stirring in the study). For scale, mechanized mixing or forced aeration could replace manual turning.

3. Inoculum sourcing and management

- To start the fermentation process, one can collect in‐house microbes from local soils, wood chips, or facility surfaces rather than purchasing commercial strains.

- Use regular inoculum refreshing and selection to maintain performance under facility-specific temperature, humidity and substrate conditions.

4. Optimizing feedstock ratios and processing conditions

- Begin with conservative kibble incorporation (e.g. ~15 %) and gradually increase while monitoring worm mortality, odor, pH and ammonia release.

- Use hardwood sawdust rather than resinous softwoods, due to lower ammonia odor and better worm palatability.

- Monitor and target lower pH, ORP and EC in fermented substrate, as these correlated with worm preference.

- Fine-tune retention times in fermentation and aeration phases based on local climate, scale and worm response.

5. Worm bed design and feeding regime

- Distribute fermented substrate in “heaps” or layers in vermibeds; the study used ~3 kg heaps in 110×90×60 cm boxes with ~100 worms/kg litter.

- Maintain moisture (~50% final dry weight in study) and appropriate bulking material (e.g., cardboard chips) to adjust texture.

- Feed continuously (e.g. 20 kg/week per module in the study) and monitor worm–substrate interaction (worm density, migration, consumption) to detect feed refusal or toxicity.

6. Harvesting, quality assurance, and downstream value

- After vermicomposting, dry and sieve the vermicompost to <1 mm fractions. Test for total and mineral nitrogen, organic carbon, trace metals and pathogen absence to ensure compliance with standards.

- For agricultural customers, tailor vermicompost features by adjusting pre‑treatment ratios to deliver either high nitrogen (for crops) or higher carbon stability (for soil carbon projects).

- The resulting vermicompost can serve as a value‑added co‑product (e.g. specialty organic amendment) or be integrated into corporate sustainability credits or carbon sequestration strategies.

7. Pilot programs, risk mitigation, and scaling

- Begin with small pilot lines (e.g. 500 L modules) to validate worm health, substrate palatability, and agronomic results under your local climate and waste composition.

- Monitor for ammonia spikes, temperature excursions, or inhibitory compounds (resins in softwoods, heavy metals) that might harm worms.

- Conduct life‑cycle and economic assessments including labor, infrastructure, energy, and end‑product revenue to ensure financial viability.