A new term has likely emerged in your lexicon over the last couple of years: sustainability. Is it the latest buzzword? Is it more than a fad?

The root word, sustain, means "to keep up or keep going, as an action or process: to sustain a conversation." So sustainability is an action or process that is ongoing. A sustainable process is one that can keep itself going.

Now think of it in terms of a planet. The population in the US exceeded 300 million this year. In the next generation, the world's population is expected to exceed 8 billion. How is the planet to keep itself going with continually greater demands on its resources?

More than recyclable and renewable

From a broader perspective, sustainability refers to providing for the needs of the current generation without compromising the ability of future generations to provide for their needs. Simply, sustainable development minimizes the use of nonrenewable materials and energy in satisfying today's needs.

Sustainability is more than a recyclable package. Sustainability is more than renewable materials. Once you stop to think about the concept, minimizing energy usage, water usage, waste and pollution can apply to everything you do. It will touch everything in your life, both professionally and personally.

So, you're really interested in sustainable packaging. What is it? Who's got it?

Absolutes or continuum?

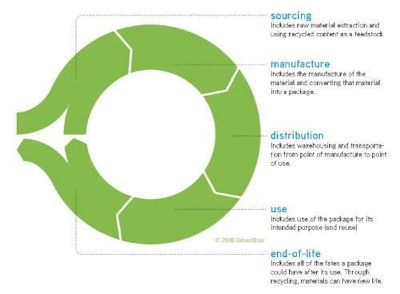

Fitting packaging into the definition above, sustainable packaging is developed by minimizing the natural resources, energy and disposal effects of packaging. Are there sustainable packages? It depends on whether you consider the definition in terms of absolutes or a continuum.

Think of the journey as an aspiration to create packaging whose lifecycle is a closed loop, cyclical in nature. Waste throughout the process is minimized. Materials are reused to make new packaging. The amount of greenhouse gases (GHG) and CO2 emitted to the atmosphere and waste in the landfill is reduced.

The Sustainable Packaging Coalition (SPC) has created an eight-point definition that describes the absolutes of sustainable packaging (see "8 sustainability criteria" on p. 24). Practically, packaging professionals must realize these virtues of sustainability represent a continuum on which to judge current packaging systems and base future design criteria.

Are there examples of sustainable packages in the marketplace today? Certainly, there are many, if you accept sustainable packaging as an aspirational goal and not an absolute one. Packages such as glass bottles and aluminum cans have been collected and reused or recycled for decades. Flexible packaging offers source reduction options that minimize package weight. Corrugated packaging provides a highly sought after waste stream for recyclers.

Four suggestions

When asked how petfood packaging in all its shapes and sizes can be more sustainable, I offer these suggestions:

1. Minimize the use of excess packaging. Using as little material as possible is the single biggest contributor to GHG reduction. Not only does it take less material and energy to make the package, but it also takes less energy to transport it. Don't overlook the opportunities to reduce secondary packaging.

2. Maximize the use of renewable/recycled materials. This extends the earth's ability to support an evergrowing human population. Many bio-based materials also provide substantial ecological benefits during their growing cycle. Using recycled materials provides an opportunity to recover valuable raw materials, thereby providing an opportunity to create economic value by eliminating the basic extraction and processing steps.

3. Design for recyclability or compostability. This helps reduce the ever-growing problem of human waste. Nobody wants a landfill in their backyard. As packaging is one of the largest contributors to municipal solid waste, it is incumbent on the packaging industry to develop solutions.

4. Use materials that are safe in all end-of-life scenarios. Promote the safe incineration, landfill, recycling or composting of packaging waste. Packaging that can be safely harnessed by any method will be much easier to integrate into any waste management stream.

Recycling flexible packaging

Today, it is important to keep in mind that, when compared to alternatives, flexible packaging options offer petfood manufacturers a more sustainable system than any other. The packages are very lightweight, many are made principally from renewable materials, they are efficient to transport,and they perform their intended function reasonably well.

However, flexible packaging is often criticized because it is difficult to recycle. Well, don't despair. Today's recycling system is highly focused on only a few materials: corrugated paperboard, office paper, newsprint, aluminum, steel, polyethylene terephthalate and, in some cases, polyethylene.

Most materials collected in municipal recycling schemes do not actually get recycled because there is no market for the recycled material. In light of these limitations, one can argue that focusing on developing a petfood package that is recyclable will have very little value if it is not actually recycled.

Organizations like the Flexible Packaging Association and SPC are working to address the issues that limit the recycling of petfood packaging materials. By focusing on the needs of the recycler and pooling the efforts of the entire packaging supply chain, these issues can be solved.