Manufacturers of pet jerky treats should consider following jerky meat guidelines from the US Department of Agriculture (USDA) to build safety into their products, said Liz Boyle, PhD, professor and extension specialist in the Department of Animal Sciences & Industry at Kansas State University (KSU). A HACCP expert, she spoke during the KSU Pet Food Experience and Petfood Innovation Workshop held September 13-15 at the university in Manhattan, Kansas, USA.

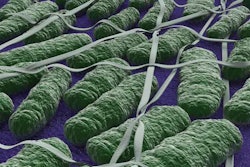

Many jerky products, whether for humans or pets, are made by dehydrating strips of meat, but that process is not enough to ensure that contaminants or pathogens such as Salmonella will be killed, Boyle said. In fact, if Salmonella is present, dehydration dries out those organisms, too, actually making them heat-resistant and more likely to survive, Boyle added.

To address this issue in the processing of jerky meats for humans, USDA’s Food Safety and Inspection Service developed compliance guidelines years ago, including an Appendix A that Boyle recommended as a good guide and checklist for pet jerky treat makers to ensure lethality of their processes in killing pathogens. She also recommended a paper by Buege et al. published in the Journal of Food Protection (2006).

Boyle was among several KSU faculty, staff and students presenting their latest research as part of the second annual Pet Food Experience on September 14. Other sessions covered timely topics such as proteins in modern pet foods, sensory analysis of extruded pet food with rendered protein meals, sorghum-based pet food and comparative nutrition in other species.

Petfood Innovation Workshop, held September 15, built on those topics with hands-on demonstrations of making jerky treats with kangaroo meat and faba bean protein, using specialized equipment to produce formed jerky treats, comparing the functional and nutritional benefits of spray-dried plasma, producing semi-moist dog treats with a high-protein hydrolyzed powder, making a meat snack with stabilized rice bran and using freeze-drying to produce protein ingredients or pet treats or foods.

The next edition of Petfood Innovation Workshop will take place April 3 at the KSU Olathe campus, in conjunction with Petfood Forum 2017. A new Petfood Technology Workshop Mexico debuts December 5-6, 2016, in Ensenada, Mexico.