According to a recent presentation given by Caroline Smith DeWaal, food safety director of the Center for Science in the Public Interest ( safefoodinternational.org ), pet owner's perspectives on the importance of food safety and traceability practices have been shaped by recent recalls in both human and pet foods. Despite modern technology, reported cases of foodborne illness, contaminated ingredients and unknown sources of origin are on the rise. Governments, consumers and company stakeholders expect unblemished safety processes from barn-to-bowl, and they increasingly do not care where in the supply chain the failure occurs, points out Melissa Hersh and Hester Shaw in their Food-Safety Strategies white paper. Consequences for growers, processors, manufacturers, distributors and retailers are serious and can result in significant financial damage.

Retailers, once mostly shielded by their branded vendors from reputational harm, now face significant exposure through their own private-label petfood brands. To minimize potential liability and financial damage, organizations need to be proactive and have demonstrable systems in place to protect pets by managing petfood-safety risks across their supply chain. If your company is part of the chain of custody, your reputation and financial performance are at risk.

Regaining consumer confidence

According to research conducted by the Center for Science in the Public Interest in the 2009 report Consumer Perspectives on the Importance of Improved Food Safety and Traceability Practices Worldwide, Americans' confidence in food safety is plummeting:

- 78% of consumers do not believe that food is safer now than a year ago;

- There is a 48% decline in consumer confidence, overall;

- 46% admit to worrying about their pets getting sick from food; and

- 52% have only some or little confidence in the food inspection systems currently in place.

Complicating matters for both petfood safety and supply continuity is the increasingly global nature of growing locations, processing, packaging and markets. Petfood supply chains are now exposed to more points of hazards, contaminants, spoilage, delays, disruptions and third-party participants. According to Food-Safety Strategies, decentralized petfood production, outsourcing/offshoring of packaging, foreign sourcing and outsourced logistics operations that move and store food-related goods, can increase risk exposure.

To combat the growing risks, all commercial operators in the supply chain should consider enacting more stringent controls and increasing their petfood-safety vigilance both within their internal operations and across their supply-chain partners.

Don't beat the system, set the curve

The modern petfood control system shifts the focus of product safety strategies from response and recovery following a contaminated product reaching consumer markets, to strategies of prevention. It is critically important that organizations understand the shift underway in which the primary responsibility for implementing and monitoring food-safety strategies is now falling to industry.

Government regulations, best-practice guidelines and other incentives aimed at the petfood and feed industries have helped prevent supply-chain failures and encourage safe petfood production, but more still needs to be done to help boost pet owner's assurance. For instance, industry-imposed safety standards can serve multiple purposes, including:

- To safeguard consumers and their pets against the harmful effects of contaminants;

- To ensure access to safe sourcing impacting operational continuity for petfood producers; and

- To protect local production capabilities and trade relationships at the domestic, regional or global levels.

You cannot rely on regulatory authorities alone to assure full application and compliance to safety standards - importing and exporting markets may have different standards. Currently, many efforts are underway to improve traceability in the US and abroad. US initiatives include the Produce Traceability Initiative , The National Animal Identification System , establishment of FDA's new foreign offices, country-of-origin labeling and pending federal legislation. International efforts involve the International Organization for Standardization (ISO) definitions, World Health Organization (WHO) programs and the European Union's TRACE project, which seeks harmonization through uniform standards that track through different technologies.

Best practices to follow

So what should you be doing to ensure the safety of your product from barn-to-bowl? Try sticking to this checklist:

- Undertake a supply-chain vulnerability assessment.

- Enhance policies and procedures.

- Strengthen supporting technology.

- Apply risk transfer at critical points.

- Ensure you have sufficient marine cargo and rejection insurance that covers physical product damage incurred during transit and the costs related to goods that you ship that are refused by your buyers or halted by a customs agency.

- Appoint a chief petfood officer or a petfood safety.

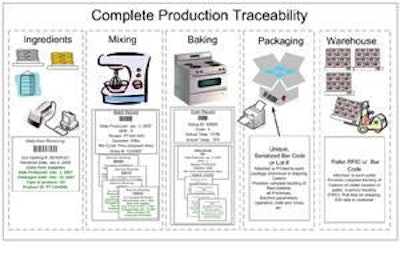

Traceability is the ability to accurately record and report on what ingredients, processes, machines, operators and recipes were used in the production of your petfood and treats. Your processing facilities need to be able to assure consumers that quality ingredients are used in the production of your petfood products.