There are two major product formats of wet petfood: chunks in a solid background matrix, sometimes called chunks-in-loaf (CIL), and chunks-in-gravy/chunks-in-jelly (CIG/CIJ). Paté formats are also popular, especially for cats, but can really be considered as a comminuted CIL format. These formats are typically packaged in cans, trays and pouches.

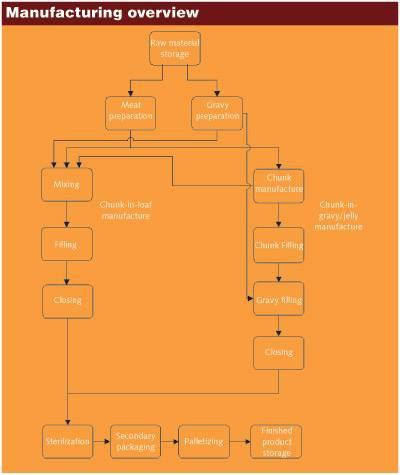

The differences in equipment and processing required for these different product and container formats will be described in this article. Figure 1 demonstrates an overview of the major steps involved in the production of the CIL and CIG/CIJ product formats.

Raw material storage

The meats used in the production of wet petfood are generally a combination of high-quality meats (livers, kidneys, hearts) and those unsuitable for human consumption. Ideally, these meats should be chilled at the source, sorted to remove foreign bodies and then frozen into solid blocks. Once frozen, the meats can be easily transported on pallets and stored in cold storage. Typically, they are stored at -18°C and should have a shelf life of many months.

For larger production operations it can be advantageous to transport them from the source in a fresh, chilled state (0-2°C) and then store them at the production facilitythus eliminating the cold storage operation.

Methods used for powder storage, such as flours and sugars, depend on the production scale. A small facility may dispense powders directly from the bags as supplied, while a larger facility may use bulk silos refilled from road tankers.

Liquids generally do not present any real storage challenges. Small quantities may be dispensed by hand, while larger quantities are easily stored in vessels and pumped to the point of use.

Meat preparation

Meat preparation involves several stages, depending on the intended use. When starting with frozen meat in blocks, the first stage involves pre-breaking into convenient-sized chunks for the coarse grinder. Most machines use some form of rotating claw bearing against a stator.

The pre-broken material then passes into a coarse grinder. The most common construction uses a circular hole plate with a rotating knife bearing against it. The meat is fed into a hopper, where a compression screw feeds it to the cutting assembly. Equipment designs are available which combine the pre-breaker and coarse grinder into one unit.

When discrete chunks are required in the final product, the frozen blocks are usually partially thawed and passed into dicers with guillotines or vibrating saw blades at right angles. Both two-dimensional and three-dimensional cutting can be achieved. The range of meats suitable for this purpose (e.g., lung, liver, kidney, heart, some poultry) is of limited availability and expensive, and hence, is generally only used for premium products.

The coarsely-ground material may be used directly if some particulate nature is required in the product. When meat emulsion preparation (used in manufactured chunks) is required, then further grinding is added to the process.

Fresh meats can be processed similarly, except that the pre-breaking stage is not required.

Gravy preparation

The gravy used for petfood production is often quite complex and must consider flavors, colors, vitamin and minerals, pH control and both filling viscosity control and finished product consistency. The gels and thickeners used for viscosity control and product consistency need careful mixing with water to avoid formation of lumps. The best equipment designs for this purpose use a high-speed rotor in the vessel containing water, which ensures the correct turbulence to draw powder rapidly into the rotor. This ensures each particle is surrounded separately by water before hydration occurs.

Chunk-in-loaf (CIL) preparation

The CIL format is usually a mix of manufactured or natural chunks with coarsely-ground background meats suspended in a loose or solid gel matrix. This format is usually filled into cans and trays. Figure 2 indicates a typical flow diagram for an automated operation.

The meat ingredients and gravy are typically metered into the mixer. The mixer must be able to generate a homogeneous mix in a short time, without causing ingredient damage. There are many mixer designs available, including single/twin shafts with various rotor designs. Twin-shaft mixers generally give more rapid mixing, and paddle rotors are preferred over ribbons. Probably the best overall design uses twin intermeshing paddles in an asymmetric trough design, as illustrated in Figure 2. This gives rapid, intimate mixing but is a gentle action with slow rotor speeds.

Mix viscosity control is the key factor in successfully filling this product format. This is achieved by a combination of gels and thickeners in the gravy, along with temperature control. When using all frozen meats, the mix temperature will generally be too low for optimum filling (30-40°C). Direct steam injection is the preferred method for mix temperature control.

Lobe pumps are usually used to transfer the mix to the filler. To minimize product damage, they should have large clearances and operate at a low speed. Metal detection/rejection is usually performed during this transfer. The use of strong in-line magnets before the metal detector can be useful for removing ferrous metal and reducing the detector count.

Volumetric fillers are usually used for CIL products. They typically use a piston to suck the product from a reservoir and then discharge it into the final container. The volume, and hence weight, of the product discharged is controlled by varying the stroke of the piston. Rotary fillers are capable of achieving speeds up to 1,000 containers per minute.

For cans, the seaming is performed mechanically using a rotary seamer. Depending on the number of seaming heads, speeds of up to 1,000 cans per minute are achievable. A plastic compound applied to the can end softens during sterilization and helps to provide a hermetic seal.

For trays, an easy-peel lid is often desirable. This is usually sealed to the container by applying heat and pressure to melt plastics on the lid and container. Seal contamination is much more critical and requires careful design of the piston outlet and the mix viscosity to eliminate dripping as the containers move from under the piston. For this reason, the slow-speed indexing fillers are the most appropriate.

Chunk-in-gravy/chunk-in-jelly (CIG/CIJ) preparation

Manufactured chunks are normally used in the preparation of CIG/CIJ products, except for some premium-priced products, which include diced natural chunks. The reconstitution of lower-grade meats into aesthetically-pleasing simulated meat pieces is a key feature of product preparation. A number of technologies have been developed for this purpose, the most widely-used being:

Heat setting of meat proteins;

Gel setting; and

Extrusion/textured vegetable protein (TVP).

Extrusion technology is complex and expensive, and only the largest petfood producers manufacture in-house. Generally, the product is bought in a dried format and hydrated before use. For this reason, only the first two technologies will be discussed.

Heat-set chunk technology

Figure 3 indicates a typical flowchart for heat-set chunk manufacture. The most important criteria for successful chunk manufacture are:

Fine grinding to minimize bone particle and meat fiber size. This is to avoid spreader blockage.

No ice present in final meat emulsion in mixer to ensure all water is bound during cooking.

No localized overheating in grinders to avoid pre-coagulation of meat proteins.

Temperature control of the meat emulsion before and during the emulsification process to maximize water bind and emulsion stability.

Minimum temperature of 85°C after cooking to ensure all meat proteins are coagulated and starch from wheat flour is gelatinized.

The slotted-ring and cutting-rotor types of fine grinders are probably the best for the intended purpose. The twin-shaft intermeshing paddle mixers described previously are the best for mixing the meats with the salts and flour (if used). This mix should stand for a while to allow maximum extraction of soluble proteins before the final stage of fine grinding, which should increase the temperature to 15-20°C.

The meat emulsion is then pumped to the spreaders. The emulsion is usually spread in strips or sheets onto the solid belt of the cooker. The main principle is to get an even thickness across the belt.

There are two main types of ovens used for cooking: gas heated and steam heated. Historically, gas ovens (either direct gas flame or indirect hot air) have been used, but steam ovens are being used increasingly, as they are cheaper to buy and operate, give a more even cook and don't catch fire.

The design of the oven is critical, the most important factor being to ensure that there is turbulent steam flow along the whole length to ensure that condensate is stripped from the surface of the meat. This is achieved by the correct profile of the hood above the belt. Extraction fans at the entry and exit remove any surplus steam. The meat strips or sheets exiting the oven should be relatively dry and have a minimum temperature of 85°C.

The simplest and most common cutter is the "lawnmower" design, although there are a number of other more specialized cutters available. The "lawnmower" design utilizes a number of spiral or straight blades rotating against a deadplate. When processing strips, the lawnmower cutter is fed the meat directly off the belt. When processing sheets, this cutter is preceded by a slitter, which cuts the slab longitudinally with circular blades.

The chunks should then be cooled further (<20°C) if they are to be stored for any length of time. The chunks can be added to a CIL recipe or mixed with gravy or jelly to form CIG/CIJ products.

Gel-setting technology

There are a number of gel-setting technologies available, with one of the most common using alginates. This relies on the action of a calcium salt on sodium alginate to form a strong, flexible structure unaffected at sterilization temperatures. The procedure is straightforward: a meat emulsion is mixed with a sparingly soluble calcium salt, such as calcium sulfate, and then rapidly mixed with a sodium alginate solution containing a calcium sequesterant to control the rate of setting. This is typically complete in a few minutes. The rate is affected by calcium salt and sequesterant conditions, pH and temperature. Figure 4 indicates a typical process sequence.

The preparation of the meat emulsion is similar to that for heat-set chunks except that low-grade meats can be utilized. Rapid mixing of the meat emulsion and alginate solution is essential. This is conveniently performed within the final meat grinder. A convenient way of forming the chunks is to spread the final mix onto a belt moving at a rate consistent with the setting time. The mix thickness dictates one chunk dimension, the other two being created by cutting the slab longitudinally with circular blades and then transversely with a "lawnmower" cutter.

Alginate chunks do not give very attractive CIG/CIJ products, but they are very suitable as an inexpensive chunk ingredient in CIL products.

Chunk transport and storage

Trough belt conveyors are very convenient for moving chunks as they minimize chunk damage, but they need careful design to remain hygienic. It is useful to de-couple the chunk production operation from the product filling operation, as it is undesirable to keep stopping and starting chunk production. Suitable buffer storage can be provided using an arrangement of belt conveyors to build up a bed of chunks which are drawn off as required.

Filling options

The filling of the CIG/CIJ products can use either the piston fillers, as described previously, or use a two-part filling process.

In a two-part filling process, the chunks can be filled by volume or by weight: the former being most appropriate for the larger quantities required for cans, while the latter gives more accuracy for the smaller quantities in pouches.

One of the more common volumetric fillers uses a pocket design. These pockets descend from the bottom of a rotating horizontal cylindrical bowl. Chunks are dispensed into the bowl and fill the pockets. Cans are fed into the filler and located under the pockets. A static plate covers the pocket outlets until the surplus chunks are cleared and then uncovers the outlets to allow the chunks to drop into the cans. This type of filler is capable of working up to 600-800 cans per minute.

Weigh fillers most commonly work on the principle of filling a number of small containers suspended on load cells. The chunk-feed system has a cut-off device which stops the flow of chunks into a container when a desired weight is reached. These weights are set to a fraction, say 25%, of the desired final filling weight. A combination of the small containers which gives the closest approximation to the final weight is then dispensed. Weigh fillers are relatively slow, but line speeds of up to 250 containers per minute are now available.

There are two main principles for filling the gravy into the containers: filling to a given headspace and fixed-volume filling. Filling to a fixed headspace gives a much more accurate fill weight. One simple and cost-effective way of achieving this is using a "brim and tilt" device. The cans pass under a cascade of gravy and are completely filled. They are then tilted to an adjustable angle to spill gravy and achieve the desired headspace.

The main disadvantage to this type of filler is that it is unhygienic. The cans require washing after seaming, and if a jelly-type gravy is used, then solidified gravy tends to build up around the filler.

A more hygienic, accurate but expensive alternative is a vacuum filler. Vacuum fillers are usually rotary devices where cans are placed under a number of turrets rotating in a circle. The outlet of each turret is a tapered plug which descends and seals into the top of the can. A vacuum is applied to the turret, thus evacuating the air from the can. The gravy supply is next connected to the turret and fills the voids. Finally, the outlet of the turret is closed and the can exits. The headspace is controlled by the depth to which the tapered plug descends into the can.

For containers filled accurately with a weigh filler, fixed-volume filling is fine and can be performed using a piston filler or a fixed-time dispense from a metering pump. While the vast majority of meat and cereal loaf-type products will be filled using a single-fill operation, the analogue in jelly will almost certainly be a two-shot fill with the meat analogue filled as one shot, followed by the jelly or gravy as the second fill shot.

There are variations where a number of different analogues or chunks may be contained within a single product. These can have a single shot for each, plus a final shot for the liquid content. Fillers, like closing machines, are usually dedicated to a single package type. Important considerations for the choice of filler include accuracy, cleanliness of fill, speed, fill range and product viscosity/consistency.

Sealing/closing

Closing cans and trays uses the same procedures as for CIL products, described previously. Pouches are usually heat sealed using heated jaw clamps. The pouch should be steam purged after gravy filling, and immediately before closing, to remove air.

Sealing/closing is one of the most critical operations in the manufacture of heat-sterilized wet petfoods. Ensuring a hermetic seal is absolutely essential in providing a safe product which will meet the required shelf life.

Sterilizing-The retort process

Together with sealing/closing, sterilization is the other most critical operation in the manufacture of wet petfoods. The choice of sterilizing equipment is precisely the same as for human foods. For conventional cans, there is the choice of various batch steam retorting systems to continuous hydrostatic sterilizing. Deciding which to use is normally driven by the throughput and flexibility required.

For aluminum laminates (trays and pouches), it is necessary to use over-pressure retorting. Again, a variety of different equipment is availablewhich needs careful evaluation. Techniques for these package types range from over-pressure air retorts to raining water systems. Recently, continuous over-pressure hydrostatic units have been developed.

The important objective of heat processing is to achieve commercial sterility. To achieve this, it is necessary to give sufficient heat treatment to destroy heat-resistant pathogens. The actual conditions of time, temperature and pressure must be carefully determined for each product and pack type.