Read more about the hi-tech equipment from Dinnissen and other processing best practices used at Jonker petfood in the Netherlands.

Getting it done with Dinnissen

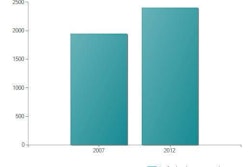

When Jonker decided to set up its third extrusion line, the

company was not just looking for extra capacity but also for

high flexibility, the most advanced technology of the entire

extrusion process and to gain both in cost efficiency and

product quality.

Jonker found the right partner with Dinnissen, explains Martin

Sonneveld, who closely followed the extension project, which

was completed and fully operational by 2007. The new line,

called Magi-N.ext, was adapted to fit inside the existing

building and completed with dosing silos for finished product

and a system to minimize contamination and manual cleaning.

"The Magi-N.ext's major benefits for us are the ability to

switch fast and efficiently to new products and recipes,

enabling us to produce a wide variety of petfoods of different

kinds and range-like standard to premium and superpremium-all

from the same single line," says Sonneveld. "We also realize

savings in terms of energy consumption and production costs due

to downtime reduction."

The Dinnissen line is easily accessible for

maintenance-moisture and steam is removed from the production

line at several locations, limiting cleaning time to a minimum,

while complying with the strictest standards of hygiene which

is essential in terms of product quality at Jonker.

Other new items introduced with Magi-N.ext are a method to add

and blend pigments before they go in the preconditioner,

precisely and homogeneously via a continuous dosage system.

This method avoids any possible formation of lumps or

undesirable colors in the extruder and obtaining a uniform and

consistent final result on the kibble.

"The Pegasus vacuum coater makes it possible for an accurate

and homogeneous distribution of fat and liquid palatants, and

the weighing and dosing of precise amounts of

micro-ingredients-such as powdered flavor enhancers, vitamins,

enzymes and other additives-that is particularly critical

especially when working with big volumes as we do," Sonneveld

says.