Dilute phase pneumatic conveying is a popular choice among pet food manufacturers for transferring dry materials. Using air as a conveyance medium has a number benefits over mechanical methods, including better protection of ingredients from contamination, ease of cleaning, lower maintenance demands, and enhanced worker safety thanks to fewer moving parts.

Schenck Process, the global leader in industrial measuring and process technologies, has made dilute phase conveying even better with the introduction of Enhanced Dilute Phase Conveying technology, or EDIP.

“There hasn’t been a lot of change in the field of dilute phase conveying for many years,” says Todd Vincent, electrical engineering manager in research and development for Schenck Process. “The EDIP technology is revolutionary.”

EDIP addresses a long-standing challenge in dilute phase conveying: Materials vary widely in weight and density, and they require different air velocities to propel them through the system—but most dilute phase conveying systems operate at only one speed. To compensate, the system designer must choose a blower model and speed based on the materials that are most difficult to move. As a result, the blower ends up rotating faster than needed when lighter or less dense materials are in the convey line.

This state of affairs produces several undesirable outcomes:

- Excessive power consumption

- Wear and tear on equipment as fast-moving materials abrade the inside of the line

- Material degradation

- EDIP changes all this. It monitors the dilute phase conveying system and translates information about materials and equipment to maintain the proper velocity. The blower speed goes up or down as conditions require. The result is a dilute phase system that:

- Dramatically reduces power consumption (typical energy savings range from 20 to 40 percent).

- Prevents excessive system wear.

- Leads to less degradation of conveyed materials.

Putting EDIP to work

EDIP is appropriate for both new and existing dilute phase conveying systems that use a positive displacement blower. The only requirements for existing lines are that they are equipped with a variable-speed blower drive and a pressure sensor/transmitter inside the line.

Schenck Process has developed two products that enable quick, easy implementation of EDIP in both PLC and non-PLC environments. The first is the EDIP Calculation Module, which houses the algorithms, and the EDIP Controller, which provides an operator interface for calculating blower speed, monitoring energy savings, and logging trends and related data.

EDIP Calculation Module

The EDIP Calculation Module is a small, easy-to-install piece of hardware that can serve up to eight convey lines and communicate over various industrial Ethernet network protocols. It can be incorporated into most PLC, DCS and PC-based control systems.

The EDIP Calculation Module contains the blower speed calculations needed to create optimum conveying efficiency. Functions include blower speed calculation, module health monitoring, and web page configuration. Any other logic needs for the pneumatic conveying system are handled by the plant control system.

EDIP Controller

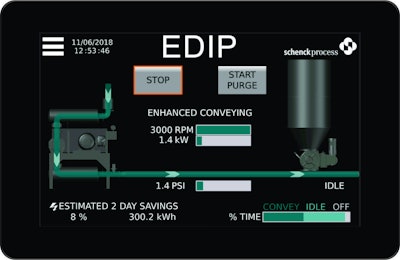

The EDIP Controller combines the EDIP algorithms with an operator interface and dedicated I/O to control blower speed in a convey system. It does not require a PLC, so it can be used in stand-alone systems. “This controller is an inexpensive way to allow the EDIP technology to be used on existing equipment with or without a plant control system,” Vincent explains.

In addition to controlling blower speed, the controller can offer accurate and timely data on the energy savings gained from implementing EDIP.

Other features of the EDIP controller include:

- A color touch screen

- Compatibility with Ethernet/IP communication systems

- Blower speed calculation

- Blower start/stop control

- Functions such as system alarms, trending, data logging, and energy savings calculation

Dilute phase conveying improvements for every plant

To find out more about EDIP technology and how it can improve your manufacturing processes, contact your Schenck Process representative today. As Vincent says, “Whether it’s our equipment or other suppliers’ equipment, we can apply this technology and improve the process for the customer.”