In September 2017, an important compliance deadline phased in for most pet food processors. Under the Food and Drug Administration (FDA) Food Safety and Modernization Act (FSMA), each facility must analyze "control points" where foodborne illnesses might be introduced, and prevent that from happening. This is called developing a Hazard Analysis and Risk-Based Prevention and Control (HARPC) plan.

Contamination doesn’t originate only in raw or spoiled ingredients; it can enter in the utilities used to operate a manufacturing process — air, water and steam. These resources, or the equipment they pass through, can transport dirt or microbes into products or deposit them on food contact surfaces.

Filtering can help manage this risk. Here are four locations to consider for filtration:

1. Compressed air

Compressed air is used for a variety of purposes in food processing. It powers pneumatic equipment, moves product through piping and adds shape or texture to food in latter process stages. It’s also used to dry equipment and surfaces after wash-downs, especially in the raw processing area.

Air compressors are a frequent source of oil and moisture, which are a perfect diet for bacteria. Moisture and oil can also deposit a permanent biofilm on piping downstream. A series of filters where compressed air comes into the facility can reduce these issues. The series should include a pre-filter (5 microns) for larger particles and a fine filter of 0.2 microns for the smallest. In between, a coalescing filter is placed to spin out remaining water.

Keeping compressed air dry discourages microbes from multiplying and also reduces wear and tear on pneumatics and air dryers downstream, improving the longevity of equipment.

2. Water and other liquids

Water is present throughout pet food processing as a major ingredient and cleaning method. It’s also used in feed boilers, steam generators, industrial blenders, gravy injectors, vitamin coaters and a host of other food contact equipment.

Safe Quality Foods, a set of industry standards widely used by food processors, recommends that “Any water … that could come in contact with the product must meet the potability standard for drinking water, which is less than 1 coliform per 100 milliliters of water.

Filtration should start in the utility room, where municipal or well water enters the plant, carrying dirt, rust and scale. A pre-filter on the water line here will trap 95 to 98 percent of contaminants 10 microns or greater, which is adequate for cleaning and sterilizing purposes. This step helps protect plant equipment from clogging and corroding, and lightens the load on more-expensive fine filters downstream.

The housing around liquid filters should be strong to resist collapse yet have media inside that preserves a high rate of flow. | Photo courtesy of Donaldson Co.

Water used as an ingredient in pet food typically goes through a reverse osmosis (RO) process. FDA requires that RO feedwater be pre-filtered to keep total dissolved solids (TDS) to a minimum. This commonly requires a 10 micron to 5 micron cartridge element. After the RO process, final filtration using a 1-micron membrane filter is recommended before the water is added to food.

3. Steam

Steam is a common method for cooking pet food and for extruding processed food into its intended size and shape. Steam also operates clean-in-place (CIP) and sterilize-in-place (SIP) systems.

The down side of steam is that its heat energy can degrade boilers and other components, especially carbon steel pipes. Even small particles in steam can clog wands and spray balls of CIP and SIP systems. Condensation that collects can also be hard on machinery and reduce energy efficiency.

An “entrainment separator” and prefilter can remove larger debris and condensation particles. But just like water needs extra filtering if it’s an ingredient, so does steam. Any steam directly injected into a product should be “culinary-grade steam,” according to industry standards. Steam is culinary grade if it has been filtered to remove 95 percent of particles 2 micron and larger. Process owners need to carefully check the micron and efficiency ratings of their steam filters to ensure they meet these specifications.

4. Storage tanks

Finally, storage is an important location on a process line. Wherever a product is held in a holding tank for a few hours, days or weeks, it can be prone to spoilage. Even a brief exposure to air can introduce bacteria, dust, pollen, water, oil aerosols, and vapors.

For many applications, a cost-efficient solution is a sterile air tank vent. Placed at the top of the tank, the vent equalizes pressure as the tank is emptied or filled. Inside, a sterile-grade hydrophobic filter element screens out particulates and bacteria from inflowing air.

A prevention plan

Pet owners have high standards for their pet products in everything from toys to grooming aids. Food quality deserves the greatest attention. Beyond harming the pet, a foodborne illness can seriously harm a brand’s reputation with consumers.

A prevention plan, including filtration, is important to meet regulations and to retain consumer confidence. With growing regulations and the complexity of process equipment, it can pay to have a qualified filtration partner involved in plant design and maintenance.

For resources on filtration in pet food processing, including a map of recommended filter locations in a plant, go to the “Regulatory” tab on this page: https://bit.ly/Donaldson-Pet-Food-Filtration.

How to select a filter

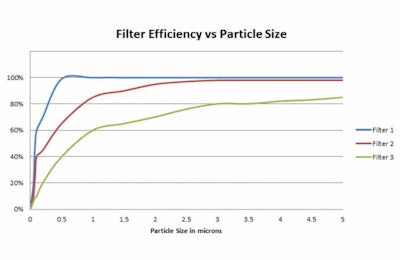

Two ratings are important in selecting a process filter: its micron rating and its efficiency. A 1-micron filter means it was designed to capture particles 1 micron in diameter and larger. Efficiency is the percentage of particles it actually captures in that range.

One filter labeled 1 micron may be 99.998 percent efficient, while another also labeled 1 micron only traps 85 percent of 1-micron particles. Ask a filtration expert what filter size and efficiency rating you need for each location in your facility.

Shown here are variations in efficiency for several filters rated 1 micron.