Protecting fragile materials during pneumatic conveying

Sponsored content

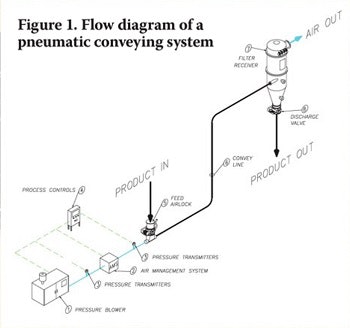

Pneumatic conveying is an effective method of transporting dry bulk materials that is clean (dust controlled) and protects the material from contamination. However, the use of pneumatic conveying to safely move a fragile or friable material that is susceptible to degradation is a concern for many pet food manufacturers.

Read more at PetfoodIndustry.com

Schenck Process engineers tailor-made pet food processes

Schenck Process has grown and expanded its product offerings to cover multiple aspects of a manufacturing operation.

Read more at PetfoodIndustry.com

How process pigging keeps pneumatic convey lines clear

Sponsored content

Process pipelines are often in need of a methodology to address issues of build-up and cross contamination. Pigging is a common technique used in liquids and oil/gas to address the concerns of both residual material and unwanted accumulation on the interior surface. A projectile (pig) is launched through the pipeline in order to scour the pipe wall and drive all contamination to the destination.

Read more at PetfoodIndustry.com

Kibble reclaim simplified

Sponsored content

Finished goods that make it all the way to packaging and subsequently need to be sent back through the process for rework can be costly for any business. For pet food manufacturers, finished kibble is often pulled off the pack line for quality checks, packaging checks and packaging mistakes, resulting in the devaluation of significant quantities of sellable product. While there are rework measures that can be implemented to send materials further back in the process for remanufacturing, a more efficient solution is to reclaim the material in its current form and repackage it as finished product.

Read more at PetfoodIndustry.com

How to improve gravimetric feeder performance

Sponsored content

What is the best way to improve my screw feeder's gravimetric performance? The first thing we need to know is what material you are feeding. Gravimetric feeder performance is most affected by how well the material feeds volumetrically. The closer you can fill the flights of the feed screw volumetrically to 100 percent, the better the feeder will perform gravimetrically. To get the material to feed better volumetrically, the material's bulk characteristics must be analyzed.

Read more at PetfoodIndustry.com