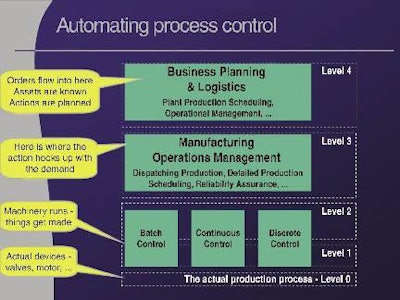

Ensuring pet food safety has always been important, but now it is in the public spotlight. Given the recent rash of pet food recalls, many pet owners are considering safety before they purchase pet food. Following is a brief overview of automating process control to ensure pet food safety.

Key questions for managers

"If you can't see it or measure it, then it is very difficult to improve it," notes Ray Bachelor of Bachelor Controls Inc. He suggests operation managers ask themselves key questions, including:

Can I prove that the products I'm shipping are safe?

Can I efficiently track ingredients received through finished goods out?

What HACCP alerts have occurred during a production shift?

Is my plant performance consistent?

Rapid response

Traceability ingredient systems are recordkeeping procedures that show the path of a particular product or ingredient from supplier(s) through all the intermediate steps that process and combine ingredients into products supplied to customers and ultimately to consumers. Says Julie Lenzer Kirk of Interstates Companies, "In the event of a product recall, manufacturers must have the ability to determine what foods are potentially contaminated and to rapidly respond to minimize the health, economic and other effects of such contamination." The speed at which this can be accomplished and the amount of product impacted again depends on the traceability systems in place.

Traceability systems have been shown to be weak or absent during a number of recent human food safety incidents. They were proven to be slow or simply unable to assure consumers of food safety. There is a wide range of traceability systems in place today from paper-based to information technology (IT) enabled. "These systems are critically reliant on the accurate recording of information," says Kirk. As a result, handwritten or printed labels are being replaced or supplemented by more effective systems that use machine-readable identification (e.g., bar codes and radio frequency tags).

Make it a true priority

Pet food manufacturers cannot afford to ignore the traceability issue, even if they have been lucky enough to avoid a high-profile contamination incident. Regardless of the regulations, since trust is the foundation for acquiring and keeping customers, making food safety and traceability a well-documented priority is an important way to increase and keep a loyal customer base.

Adopting strict standards and ensuring that enterprise and supply chain systems support the full range of food safety and traceability requirements will protect companies from a potential disaster or additional cost incurred by non-compliance with new regulations. Automating traceability is just one step in this process. It requires that quality control and lot traceability be integrated into processing and warehousing systems. These capabilities are an integral and intuitive part of operations and should be reflected as such in the systems that support operations.

Code power

Traceability is greatly enhanced through the use of bar codes for automated data collection. When supplier lot numbers are associated with a product bar code as that product is received and then scanned as it is introduced into the manufacturing process, the information can be easily traced when needed. Likewise, capturing the lot number of bulk products at receipt and usage, although prone to more uncertainty based on products mixing in a bin, helps quickly pinpoint what lots may have gone into which finished products. In the race against time in a recall or a regulator's request for information, automated systems beat a spreadsheet every time.

Send a positive message

"Traceability is not a threat," notes Kirk, "but an opportunity: a challenge to send out a positive message." Safety and traceability are integral parts of pet food quality, but they are also subject to a consumer's perception, just as quality is.