A_noina | Shutterstock.com

This product showcase features the latest micro-ingredient systems available for animal feed production.

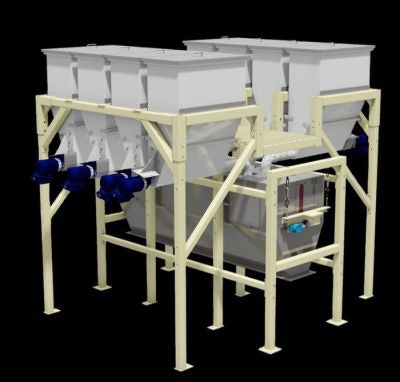

Sudenga Industries Loss-In-Weight Micros

- Fastest, most efficient, accurate batching possible because all ingredients are weighed and added automatically

- No drugs or additives are handled manually with the loss-in-weight system

- All ingredients are weighed and added simultaneously

- Continuous inventory is monitored quickly, efficiently and accurately

- Less space required than conventional micro systems for more design and installation flexibility

- Removing the auger, motor and gearbox assembly for maintenance or cleaning is quick

- UHMW bearing on the micro hopper discharge end provides maintenance-free, lubrication-free operation

CPM Automation Loss-in-Weight Scale Weighing System

- Live, accurate bin inventory is maintained because each product bin is a scale supported by two load cells

- Multiple ingredients can be weighed simultaneously

- Compact design requires less height for installation than standard micro scale systems

- Modular design allows customized configurations in clusters of four bins

Sterling Systems & Controls Micro Ingredient Systems

- Can be provided with stainless-steel bins, bulk bags, bulk totes and multiple scales

- High-quality auger feeders or vibratory feeders

- Multiple-speed feeder control

- Customized systems using standard components

- Multiple-scale systems maximize batch capacity

- High-resolution scales for best weighment accuracy

- Lot tracking and batch validation

- Gain-in-weight and loss-in-weight systems

- Supply bin inventory control

Easy Automation Rotary Dump Microsystem

- Independent load cells for bin can record bin inventory or be used for loss-in-weight applications

- NTEP-approved load cells for individual bins are available for inventory purposes

- Rotary dump assembly inside stainless-steel shroud with large access doors

- Micro ingredients are weighed in the stainless-steel drum that rotates

- Poly micro ingredient bins

- 8-, 4.6-, 5.6- and 9.2-cubic-foot configurations

- Multiple units can be configured for an infinite number of micro ingredient bins

APEC Micro Ingredient Scale

- Designed to eliminate labor costs by cutting back on the number of employees necessary to input ingredients

- Protects workers by limiting exposure to ingredients

- Newer systems are much easier to maintain than old ones

- Can be scaled to fit your unique available space