With consumers increasingly seeking eco-friendly products and brands, more and more “green” claims are appearing in the marketplace on all categories of products. Petfood is no exception.

GA Pet Food Partners can’t even make those claims—as a private-label petfood manufacturer, it doesn’t have its own products or brands—yet the company has invested heavily in ensuring nearly every aspect of its business is environmentally friendly. “It’s not just our logo that’s green,” says the company’s website.

Starting with a 10-year sustainability plan, GA staked its claim to being a leader in environmentally responsible petfood manufacturing with the recent opening of a state-of-the-art facility in West Lancashire, England, UK. Situated on a 27-hectare site bordering the designated Biological Heritage Site of the River Douglas, the facility’s green features include:

- A water treatment plant plus three biofilters (each the size of an Olympic swimming pool);

- All air and water cleaned and recycled on site, reducing GA’s environmental and odor impact on its neighbors and the local surroundings;

- A habitat creation and management plan that will help create wetlands and grasslands to encourage nesting and foraging bird species, plus add plantings of 10,000 native trees and shrubs to maintain biodiversity; and

- An award-winning, packaging recycling plant that separates paper, cardboard and plastics, significantly reducing landfill waste.

As one of the world’s largest private-label producers of superpremium dry petfoods, GA has long been known for product and production innovation. It launched a Halal cat food several years ago and last fall introduced what it calls a “world first,” a dry extruded petfood with zero carbohydrates. The innovation continues this year with Just Fresh Meat, a brand new concept and technology for guaranteeing that all meat in a dry petfood is fresh, with no dry rendered meats or bonemeals, the company says. (See “GA Pet Food’s latest product innovation.”)

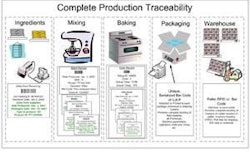

Similarly, besides its eco-friendly features, the West Lancashire plant includes a fully automated distribution center, the world’s first thermal twin extruder (from Wenger Manufacturing) and other technologically advanced equipment. The company maintains a Grade A rating from the British Retail Consortium Global Standard for Food Safety. Its last BRC audit earned GA praise for its IT systems, which are paperless, real-time and control, monitor and report all functions from the intake of raw materials to distribution of finished petfood, says the company website.

With the new manufacturing facility, the company is proving it won’t rest on its laurels, especially considering its sustainability initiatives have only just begun. “The GA 10-year plan sets out the proposed development of our production site, including a new raw material mill, comprising 7,500 tons of raw material storage in 64 bins, able to blend and grind the raw ingredients ready for extrusion,” says David Bennison, GA sales director.

The sustainability plan doesn’t focus only on manufacturing, packaging and their outputs, as critical as those elements are to reducing environmental impact. GA also turned to its clients and the community in developing the 10-year plan. “The business needed to obtain consent from all stakeholders for a long-term plan that would deliver the production capacity demanded of us by our customers, requiring ever-greater complexity with traceability, as well as lower cost,” Bennison says. “The local community wished to be certain that we could cope with any potential odors that were generated, particularly given the use of 100% fresh meat.”

Bennison adds that involving the local community meant consulting every one of the 2,500 households in the area and inviting area residents to “Open Days” to seek their approval of GA’s plans. “Eighty-nine percent of local residents were fully supportive, with a further 8% having specific concerns, which we were able to satisfactorily resolve,” he says. “The involvement of the community is a continuous effort and will remain so, if we are to retain their trust and confidence. Our neighbors need to be confident that we can live and operate 24/7 within our community without causing a continuous stink from our petfood plant.”

Clients and community members are not the only stakeholders involved. “The 10-year sustainable plan involves every employee and affects them in every way,” Bennison emphasizes. “We need a business that is profitable, so as to provide jobs and opportunities for our people to grow and prosper. Our employees live in the local community and it is important that they are proud to do so.”

Embarking on such a plan, especially that state-of-the-art facility, does not come cheap, Bennison acknowledges. “The sustainable plan is expensive to operate. However, we now have a future that allows us to produce premium-quality petfood without affecting our neighbors or the environment.”

Every business needs to be sustainable in terms of economics and the impact that it causes, Bennison continues, saying dry petfood manufacturers, particularly those in Europe, need to pay special attention to odors generated from the cooking and drying processes. “These odors are offensive to local residents, and if they are not eliminated, then the Environmental Agency will eventually close the business, for local residents are no longer willing to put up with odor.”

He shares further advice with fellow petfood manufacturers seeking to be more sustainable: “Having agreed on the proposals with regulators, you need to consult comprehensively with all employees, suppliers, customers and local residents to ensure the proposals meet their concerns and give confidence that the business is truly sustainable. Without the full agreement of all stakeholders to a single strategy for the future development of the business, it is unable to have that continued support to develop.”