With an estimated 3,000 new pet food products introduced in the marketplace every year, research and development are critical to launching a successful product in a timely manner and on budget. Attendees at the 2018 Petfood Workshop rotated through different stations to participate in activities that highlighted some of the challenges to developing and launching a new pet food or treat product.

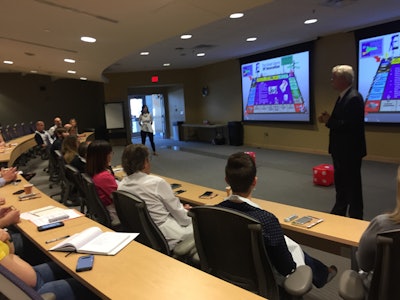

New product launches don’t always go as planned, costing time and resources. “The Great Game of Incuvation,” hosted by Incuvate and Kansas State, highlighted some of these challenges. Two teams each took turns rolling dice and moving around a Monopoly-like board, with different product development steps in the new product launch process, from concept development and market research, to searching for materials, packaging tests and contract negotiation, with setbacks like having to go back two steps in the process or pay more than budgeted for ingredients. When developing new products, Greg Aldrich of Kansas State said companies should try to create and launch several new products at once rather than just one new product because it makes more financial sense. He also emphasized that research and development must be a part of the company culture to successfully develop and launch a new pet food product.

Petfood Workshop attendees play the "Incuvation" game to learn about new product development. | Photo by Alyssa Conway

Formulating new pet food: ingredients

Consumers are increasingly looking for “clean-label” products not only for themselves, but also for their pets, which can be a challenge to companies formulating new pet food and treat products. A team from Isonova demonstrated how egg products can be used in products with clean labels and simple formulas. By mixing different ingredients into a vegetable oil and frying the mixture, the company demonstrated the increased emulsification properties of these egg products when used in a formula.

Ingredion also demonstrated how to identify and solve issues with pet treats that could be caused by ingredients. Participants used grain alternatives like pea flower and tapioca to create biscuits, then compared the texture of these biscuits to traditional dog biscuits made with grains to show that the same product consistency can be achieved when developing a product without grains as one with them. The company also demonstrated that gravies can also be developed as a clean-label product by using starches modified in a natural way rather than using modified food starches with chemicals. When formulating for digestive health, using prebiotic fibers containing short-chain fructooligossacharides rather than longer-chain structures helps to increase the good bacteria in the gut and are easier to break down, resulting in less gassiness and better stool quality in dogs and the need to use a smaller dose in cat foods.

Another important consideration when formulating new pet foods or treats is acceptance of the product to both the pet and its owner. Representatives from Diana demonstrated this to attendees with an activity that allowed them to work in teams formulating their own pet food kibble, and then evaluate each other’s product. The activity highlighted why toppers are used in pet food formulas to mask unpleasant odors to please pet owners but also provide a healthy, tasty product for the pet.

Other new product development considerations

Using Peterson’s salmon and beef protein products to add more protein to a product and improve bindability, representatives from Extrutech demonstrated how not only ingredients, but also equipment can affect new product development. With a table-top extruder, the company demonstrated how a simple thing like changing the die on an extruder can improve a product’s appearance. The company recommended using one of these table-top extruders for new product development because it is less costly than a commercial extruder to test new products and determine if they are feasible to produce on a commercial scale.

Prior to and after the launch of a new pet food or treat product, validation is key to ensure your product is formulated to be palatable and accepted by pets. Playing “Cards Against Validation,” attendees learned from AFB why benchmarking is so important to help change what you’re doing to improve product quality and palatability. A number of factors can affect palatant adherence to kibble, including: temperature, equipment, flowability, fat application, and kibble texture and density. Doing benchmarking through analytical tools can identify how much palatant is truly sticking to the kibble rather than just assuming you’re getting what you’re formulating for. AFB also explained the importance of doing benchmarking through taste testing and animal behavior monitoring when launching a new product to ensure pets will actually like it. Some strategies for this that AFB suggested were both paired taste comparison and monadic testing, as well as observing how a pet reacts to the food in front of them and how much they consume.

AFB hosted "Cards Against Validation" to teach Petfood Workshop attendees about product benchmarking. | Photo by Alyssa Conway

Petfood Workshop was hosted on April 23 at Kansas State University-Olathe in Olathe, Kansas, USA.