The ongoing COVID-19 pandemic has significantly shifted the way everyone does business, and food safety has not been immune to the changes.

“The commitment to producing safe and quality ingredients never changed, waivered or shifted due to the pandemic of 2020,” said Dr. Ross Hamilton, vice president for government affairs & technology at Darling Ingredients. “What did have to change, however, were the methods used to verify this commitment by the ingredient manufacturers, pet food companies, certification bodies and regulators.”

Travel restrictions lead to innovations

When lockdowns and travel bans went into effect all over the world in March 2020, decisions were made too quickly to come up with alternative plans for conducting on-site facility audits or certifications. At first, particularly in the U.S., the thought was that things would be back to business as usual by the summer. Of course that isn’t how things played out, and now, a year later, many state and local governments continue their restrictions on businesses and recommendations that citizens limit gatherings and potential exposure to the disease.

“Such restrictions, in combination with individual precautions taken to avoid exposure to COVID-19, have made it very difficult to travel to and from manufacturing locations to conduct in-person audits,” said Hamilton. “In response to this need, companies and some certification bodies have created digital or virtual audit policies, formats and procedures to verify compliance to customer and certification scheme standards. Indeed, a shift has occurred where suppliers, pet food manufacturers and certification bodies are willingly working together on the use of virtual formats to maintain and verify compliance to food safety and quality standards.”

Compliance in 2021

Pandemic or no, food safety will continue to evolve.

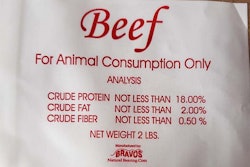

“One food safety trend is further escalation of Food Safety Modernization Act (FSMA) requirements and U.S. Food and Drug Administration (FDA) enforcement as FDA moves from reacting to food safety issues to preventing food safety concerns,” said Hamilton. “FDA continues to move towards comprehensive inspections under an Animal Food Compliance Program. FDA inspectors will be more specialized and conduct comprehensive inspections that include registrations and licensing, FSMA current food manufacturing practices (CGMP), preventive controls, bovine spongiform encephalopathy (BSE) regulations and compliance under the Federal Food, Drug, and Cosmetic Act.”

FSMA will also continue to evolve as new food safety challenges occur.

“Individual ingredient and pet food manufacturing facilities will be expected to consider such new issues in their hazard analysis and to control hazards determined to be those requiring a preventive control,” said Hamilton. “This alone means that ingredient suppliers and pet food manufacturers must maintain a robust hazard analysis and prerequisite programs, develop ongoing employee training programs and have internal controls to be sure new or modified CGMPs and preventive controls are implemented.”