With the recent recall of a series of dog food lines, pet owners across the country have had more on their minds than what to get their Great Danes or Labrador Retrievers this past holiday season. In the last month of 2011, three major recalls of well-known petfood brands were made due to aflatoxin levels that were detected above the acceptable limit. Although the products have already been recovered from store shelves and no illnesses have been reported in association with the lot productions, it is still a worry for many pet parents.

Aflatoxins are a group of highly regulated mycotoxins around the world because of their potential to induce liver cancer in humans and animals. As a result, the petfood industry is no stranger to toxins and recalled products. The earliest documented aflatoxin outbreak dates back to 1974 when hundreds of stray dogs in India died due to the consumption of aflatoxin-contaminated corn (Krishnamachari et al., 1975). In December 2005, 76 dogs were killed from aflatoxin-contaminated petfood in the US, causing a large recall.

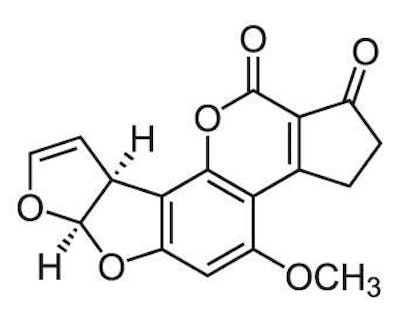

Aflatoxins are predominantly produced by Aspergillus flavus and Aspergillus parasiticus molds. These molds can be formed both in the field and during storage and are commonly found in corn and peanuts grown in regions with high temperature and humidity. Aflatoxins can be harmful to pets if consumed in enough quantities (Figure 1). The liver and the immune system are the major target organs for aflatoxins.

Since aflatoxins are regulated tightly, all petfood companies are mandated to have a program in place to monitor the incoming raw materials. However, outbreaks such as the ones discussed above do occur. Some of the reasons for this can be:

- Sampling error : 85% of mycotoxin analysis error is due to sampling. It is highly recommended to follow Food and Drug Administration and EU guidelines for sampling procedures. The success of analysis depends on how rigorously the recommended procedures are followed.

- Analytical error : Quick mycotoxin tests, based on enzyme-linked immunosorbent assay (ELISA) principles, are commonly employed at petfood plants to accept or reject food ingredients. Although these tests provide instant results and are cheaper, they are semi-quantitative in nature. This means the quantification is not accurate and may result in levels of toxin above the recommendation in the petfood. Can petfood companies employ rigorous tests, such as high-performance liquid chromatography (HPLC)? Can the grain trucks stick around the petfood plants for two days until HPLC results are made available?

- Storage of manufactured food : Aflatoxins can be formed in petfood during storage if not stored under appropriate conditions. Has this been monitored?

- Masked aflatoxins : Mycotoxins such as deoxynivalenol (DON or vomitoxin) and zearalenone are found in masked forms in grains such as corn. Can the same happen for aflatoxins? If so, can food manufacturing process make masked forms detectable? These questions need to be answered.

Ochratoxin A is regulated in some European countries but not in the US. Although not regulated, many countries have set up feed guidelines for the levels of DON, T-2 toxin, zearalenone and fumonisins. Since these are not regulated, their outbreaks don’t make the headlines. The effects of some of these mycotoxins on dogs as well as their ingredient sources are listed in Table 1.

When it comes to affecting the health and performance of pets, Fusarium mycotoxins such as DON seem to play a key role due to their widespread occurrence. Since dog food contains many different ingredients, the chances of the presence of multiple mycotoxins in dog food are very high. Such a combination can lead to the overall increase in animal toxicity even when mycotoxins are present at low concentrations. Some of the important scientifically proven mycotoxin interactions are listed in Table 2.

Although many laboratories across the world are trying to increase the number of mycotoxins tested, most of the analyses are done for the six mycotoxins discussed above. Many more mycotoxins can be harmful to animals and, therefore, their detection is important. Alltech has developed the 37+ Mycotoxin Program wherein feeds and feed ingredients can be subjected to the analysis of 37 mycotoxins using LC-MS/MS instruments. The preliminary results from the 2011 US ingredient survey have clearly indicated the presence of multiple mycotoxins (Figure 1).

Mycotoxin management is an integrated approach. It starts right from the time the crops are on the field and continues through the times of harvesting, transportation, storage, milling and feeding. The goal of any safety program for manufacturers should be to understand the level of mycotoxin challenges coming in to the supply chain so that the right steps can be taken to try and mitigate their negative effects on animal performance. This involves setting up the correct grains and food monitoring procedures as well as identifying critical mycotoxin limits for petfood. With this information, the health and wellbeing of pets can be protected from mycotoxin exposure.

In spite of following correct monitoring procedures, mycotoxins are unavoidable in petfoods. Unlike nutrients, mycotoxins are not uniformly distributed in foodstuffs, which makes accurate analysis difficult. A risk management approach should contemplate the use of a mycotoxin adsorbant capable of coping with that one chance of having mycotoxin escape detection and create harm.