Brand Insights from Bühler

Pet food producers continue to work relentlessly to increase productivity in order to minimize costs and keep their customers happy, while also maintaining the highest quality standards. As the core processing step for pet food production, extrusion plays an important role, however, it doesn’t make sense to focus exclusively on extrusion if precision material handling is not achieved in each step along the way from grinding to packaging.

Similar to smartphones and smart cars, the pet food industry is increasingly looking to smart mills as the future of pet food production. Bühler’s Smart Mill initiative began four years ago and aims to help manufacturers improve quality at pet food plants across the board, by eliminating human error, improving efficiency, and optimizing safety.

Smart Mills

There are four levels of smart mills in North America:

- Level 1 plants have machines and processes that are controlled by automation. Most of the pet food plants in North America have achieved Level 1 automation.

- Level 2 plants are digitally assisted plants and feature data transparency for informed decisions and predictive actions. Plant operators have the ability to track all data to make the best decisions today, as well as future decisions. In these plants, data should be available every minute. Approximately 70 percent of North American plants have achieved this level.

- Level 3 plants are self-adjusted, and machines and processes are optimized in a closed loop with minimal human interaction. These plants are very rare, as fewer than 5 percent of North American plants have achieved Level 3 status. Bühler offers an automation and digital subscription service to help manufacturers monitor and control production to increase raw material and energy efficiency.

- Level 4 Smart Mill plants have achieved fully autonomous mill operation through intelligent and self-learning algorithms. These are the plants of the future and no plants in North America have achieved Level 4 automation.

As the pace of technological change continues to accelerate, this might be a good time to consider what level your plant has attained, and perhaps more importantly, how you’ll reach the next level.

Smart Mill Goal

The goal of the Smart Mill initiative is to cut raw material and production costs by achieving these four targets:

- Optimize resources to obtain the highest yield. This includes optimizing labor resources while also supporting operators.

- Save energy. This is achieved through efficient energy use, reducing energy consumption, and optimizing product flow.

- Ensure quality. Real-time monitoring and digital assistance for process tracing enhance quality.

- Maximize overall equipment effectiveness. This is accomplished through higher capacity, optimal performance, and reduced downtime.

Particle Size Reduction

The granulation control loop features an Intelligent Control System, an Intelligent Adjustment System, and an Intelligent Analyze System. In the granulation control loop, particle size distribution can be precisely monitored and controlled using the hammer mill’s automatic speed adjustment and online particle size measurement.

Depending on granulation feedback for the particle size measurement, the target value is set on the Bühler control system for the frequency of the hammer mill. Consistent particle size leads to more homogenous mixing and pre-conditioning. Benefits of precise particle size distribution include:

- Uniform granulation for downstream process, mixing, pre-conditioning and extrusion.

- Real-time production data.

- Narrow start-up deviations with new products.

- Adapting to raw material fluctuations.

- Compensating for hammer and screen wear.

- Detecting broken screens.

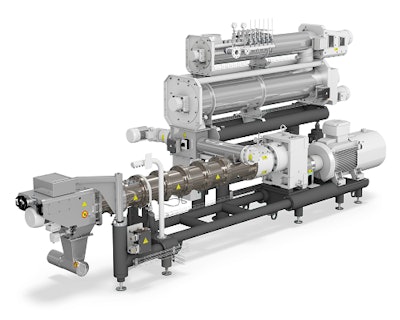

Bühler Extrusion System Focuses on Precision

The extrusion system is efficient and flexible, providing eco and specific mechanical energy (SME) control. It’s also operator-friendly, providing bulk density control of the final product, and quality control through pre-conditioner control. This enables the delivery of premium quality, precooked product before extrusion.

The extrusion system saves raw material and energy throughout the entire process and enables manufacturers to produce a wide range of product, including diverse size, shape, density and texture variation.

Pre conditioner

The pre-conditioner enables precise moisture and thermal energy management, and the multi-stage conditioning system is installed alongside the extruder for easy cleaning. Having a separate conditioner and retentioner provides a number of benefits:

- Homogenous mixing in the conditioner.

- Adjustable retention time in the retentioner.

- Thorough moisture and thermal energy penetration into dry mix.

- Guaranteed first-in/first-out material flow, and more uniformly pre-cooked material.

- Large maintenance door for conditioner and retentioner enables easy cleaning and maintenance.

In addition, large particles allow only a short time for mixing and a long time for penetration, while small particles allow a long time for mixing and a short time for penetration.

On-line Pre Conditioner Control

The Bühler system allows manufacturers to monitor pre conditioner as a critical control point, providing a warning alert before the temperature drops too low, and a critical alert if the temperature falls to the critical range. Operators can monitor the performance of the whole system, including the steam temperature of the pre-conditioner, and a higher temperature for the validation process.

Typical critical parameters include:

- Temperature at the “cooking zone” (preferably measured using a dual probe).

- Temperature of the product in the conditioner (for example, 90 C in the conditioner if running temperature is 95 C).

- Water addition (measured by a calibrated gravimetric flow meter).

- Temperature of conditioner shell (if it’s used for validation).

Forced Screw Feeder Transitions Material from Conditioner to Extruder

- Precise product flow capacity control provides a number of benefits:

- Higher throughput with forced infeed leads to greater extruder barrel fills.

- Stable running conditions provide consistent flow capacity of material from conditioner to extruder.

- Consistent product quality due to relatively stable motor load.

- The bypass flap can sort out insufficiently conditioned material during start-up and stopping procedures.

Extruder Modules Enable Precise SME and Bulk Density Control

Versatile screw configuration translates into product versatility, and the SME module and mid-barrel valve control mechanical energy input into products. The extruder module significantly reduces downtime for formulations that require different levels of SME without changing the screw configuration.

The density control system allows operators to precisely control pellet density by steam injection, venting or vacuuming. The sanitary startup discharge system (SSDS) or End Barrel Valve protects food safety. It is installed just before the die, so if the temperature of the product flow doesn’t reach the target safe temperature, it is diverted and recycled to optimize food safety and minimize waste. When the temperature of the product flow reaches the target safe temperature, it is sent to the die for cutting and shaping.

Online Bulk Density Control

SME and bulk density controls on the extruder provide a wide range of product bulk density options without the need to change the extruder barrel component. This enhances efficiency and flexibility by enabling changes to product density without stopping the line and provides SME and bulk density control at the operator’s fingertips. The advanced control system also enables automatic SME and thermal/pressure adjustment.

Bühler Dryer

Precision product moisture control and energy efficiency provide consistent and stable product moisture content and the highest energy efficiency. Benefits of the Bühler dryer include:

- Automatic moisture control that measures moisture content of the product at the inlet and outlet so the drying temperature can be adjusted to achieve the required product moisture.

- Automatic humidity control measures humidity at the top of the dryer beds. By opening/closing the valves, the ratio between recycled and fresh air volume can be controlled.

- Automatic bed depth control. By measuring the bed depth, the belt speed is adjusted to maintain optimal depth, and by adjusting the belt speed, the drying time can be controlled.

Learn More

Bühler provides innovation for a better world, helping manufacturers increase productivity, minimize costs and maintain the highest safety and quality standards. To learn more about Bühler’s single-screw extruder and see how these innovative products can help you operate more efficiently, visit our website.