It’s become a common scenario in the pet food industry: shortages, unreliable supplies or delivery delays of ingredients, forcing pet food brands to substitute and, in many cases, reformulate. If your company finds itself in this situation, you can minimize challenges and help guide the changes by taking some key steps, according to Drew Turner, regional sales manager for Coperion’s food industry markets. He shared tips and answered questions during an Ask the Pet Food Pro chat on June 8, 2022.

“The biggest thing I've basically been seeing is the fact of the cost of the ingredients at this point in time, and the availability of those ingredients,” Turner said to lead off the discussion. “Everything’s been getting kind of crazy as far as people actually being able to find the materials they’re looking for, and looking at different materials that could potentially fill the need … and also to make sure the recipe stays on track.”

How to weather the perfect storm

As in all other sectors, inflation is affecting pet food extensively, Turner explained. “The cost to make stuff went up significantly. The costs for energy, the cost for gas went up significantly as well,” he said, adding that means a company’s other costs just naturally go up. “The cost for labor went up. And being able to find labor and potentially having to overpay for labor. So yes, that is driving up the cost of ingredients exponentially. I'll call it like the perfect storm. It's kind of everything compounding on it.”

What can pet food brands do to weather the storm?

1. Monitor the situation and keep accurate forecasts, Turner alluded. Talk to your suppliers, especially ingredient providers, but also equipment suppliers. They work with many different pet food companies, so they likely are aware of issues and pending problems others in the industry are experiencing and that could be coming your way.

2. To help track potential shortages or other problems, consider installing sensors on equipment in your processing line, Turner suggested, especially if you’re looking to put in a new system. “Consider putting some extra sensors in to keep an eye on the process. And that way, you could potentially optimize that process along the way, and be able to adapt much more quickly, because you would have that data,” he said.

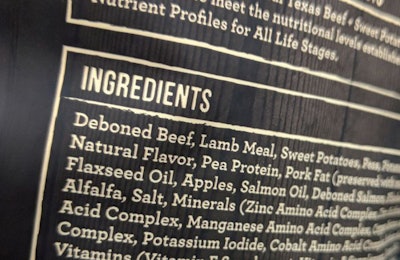

3. Accuracy is key, including to control costs. “Try not to just look at an ingredient as one ingredient swap for another,” Turner cautioned. “We’re really starting to look at accuracy as being a really good requirement. You start looking at what is the cost of adding an ingredient, and if you overfeed a little bit of that more expensive material or the material you’re finding difficult to procure, that starts to become very valuable, even above your accuracy having to basically meet the recipe. Let’s say, if you're looking at plus or minus 1% of an ingredient versus plus or minus a half a percent, the cost to make that goes up rather significantly and rather quickly per hour per batch.”

4. Changing ingredients also brings processing implications. “If you're looking to change an ingredient, what are the densities like?” Turner gave as an example. “What’s the product distribution? Does it have the same granularity? And how’s that going to mix in the process? How are you going to be able to feed that in? Look at how many grams potentially are you feeding per second, and you want to make that as consistent as you possibly can, to keep the flowability.”

5. Run tests, and turn to your suppliers for help. “We basically always recommend for a customer to reach out to who supplied the system or who helped install the system to see if they will be willing to offer any kind of testing to validate if the piece of equipment they have will work with the new ingredient and/or the changes in the recipe,” Turner explained. “So that we can have a conversation with them, the experts, and make sure it’s done right.”

If your company has the capability, running your own tests is a good idea, too, including to ensure the formulation meets nutrition-related requirements and standards. “If you have a one-off piece that you can actually run the material with and start to validate those ingredients,” that’s an important step, Turner said, but beware that there a lot of challenges with changing ingredients. Working with suppliers is usually the easiest.

“There are quite a few of us out here that will do free testing, if you just contact a local rep or contact the company through a webpage,” Turner suggested. “And you say, ‘Hey, I got this ingredient, I'm looking to potentially change, here’s where I’m at now, here’s where I’m looking to go, what would you recommend,’ and we would do a test for that, and give you the actual results, and what kind of accuracy you can expect, and so forth.

“It's hard to get hold of a piece of equipment, just to do a checkout,” Turner continued. “As a supplier, I have a lot more at my disposal. So if one option doesn’t work that I actually thought of at first, I may be able to change it and see the benefit of one versus the other. And we can offer that potentially to the customer going forward. You know, if we stay with what you have, here are the limitations; however you look to change, this may be the benefit.”

Pet food supply chain disruptions are here to stay for a while, but by carefully tracking potential issues and planning ahead, you can manage and likely prevent a crisis.