High-pressure processing (HPP) has been in use for decades, but it wasn't until the early 1990s that HPP became a commercial food preservation method. HPP uses intense pressure to inactivate microorganisms and spoilage enzymes without using high heat, which can offer pet food products extended shelf-life while preserving the food's fresh-like quality, nutritional value, flavor and appearance.

An emerging technology, high-pressure thermal processing (HPTP) represents an alternative to HPP, said Ramses Bermudez, marketing specialist with Hiperbaric.

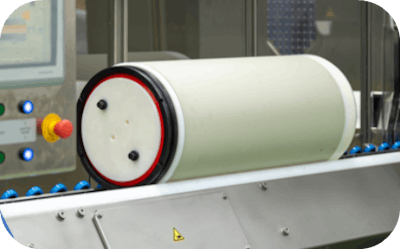

High-pressure processing (HPP)

According to Bermudez, HPP is a non-thermal processing technology that applies high pressure (up to 6000 bar) to inactivate pertinent pathogens of concern in raw and cooked pet food. Often referred to as a “cold pasteurization” method, HPP relies on pressure instead of heat to achieve its effects, using water as the pressurization medium.

This technology is applied post packaging, meaning products are treated while in their final packaging, which helps prevent any post processing contamination.

The process involves placing the packaged food products into “blue baskets,” which are then loaded into the HPP vessel. The vessel is filled with water, and additional water is introduced with the help of the intensifiers until the final desired pressure is reached.

Once this pressure is achieved, the pressure is held for a specified duration, which typically lasts between three to five minutes. After the holding time is complete, the pressure is released, and the processed products exit the vessel.

"HPP products are meant to be stored under refrigerated conditions to preserve the freshness and quality attributes of the processed products, as well as to delay the growth of microorganisms that are resistant to pressure, such as spores," explained Bermudez.

High-pressure processing (HPP)Hiperbaric

High-pressure processing (HPP)Hiperbaric

High-pressure thermal processing (HPTP)

HPTP is a thermal technology that combines high pressures, reaching up to 6000 bar, with high sterilization temperatures of up to 250°F. This method is designed to inactivate pressure resistant spores and create shelf-stable products.

Unlike traditional HPP, HPTP requires two additional steps: a preheating step before the application of pressure and a cooling step afterward.

High-pressure thermal processing (HPTP)Hiperbaric

High-pressure thermal processing (HPTP)Hiperbaric

Unlike HPP, which uses standard blue baskets, HPTP requires the use of insulated canisters. These canisters are preheated before loading into the equipment for pressurization. By incorporating heat into the process, HPTP achieves greater microbial inactivation than HPP, and when operated at moderate temperatures, it can also be used to produce chilled-stable products with extended shelf life.

"The combination of preheating with the sharp increase in temperature caused by adiabatic heating results in significantly reduced processing times compared to traditional retort processes and results in a lower thermal load on the products," Bermudez said.

The Commonwealth Scientific and Industrial Research Organization (CSIRO), Australia's national science agency, invented the insulated canister technology, which Hiperbaric refined to develop HPTP. The canister is licensed for exclusive use in Hiperbaric HPP units, noted Bermudez.

While this system has already been installed in research centers, it has not yet reached commercial facilities. Bermudez said Hiperbaric's goal for HPTP is to provide pet food producers with a method for creating shelf-stable products that combine robust microbial inactivation with a reduced thermal load compared to traditional retorting.

"We are currently working closely with a leading pet food manufacturer to implement HPTP in production environments, an important milestone that will define its path to broader availability," said Bermudez.

HPTP not intended as a pre-freeze-dry kill step

Bermudez noted it is important to clarify that HPTP is not intended to be used as a pre-freeze-dry kill step.

"Instead, HPP is fully compatible with freeze drying," he said. "Since both are non-thermal preservation methods, combining them allows manufacturers to deliver premium, safe, shelf-stable pet food that retains the nutrients and natural benefits of raw diets."

The raw HPP freeze-dried category illustrates this synergy, said Bermudez. Typically, production begins with a formulated blend of raw ingredients packaged into chubs. These undergo HPP at pressures up to 6,000 bar for three to five minutes. Afterward, the material is processed in a clean environment into bite-sized shapes before freeze drying.

HPP serves as the validated lethal intervention step, achieving a 5-log10 reduction of key pathogens such as Listeria monocytogenes, Salmonella spp., and E. coli.

"This step is particularly critical given the history of recalls in the raw pet food sector," said Bermudez. "Freeze drying significantly extends shelf life while preserving the sensory and nutritional quality of the final product."

HPP vs. HPTP

According to Bermudez, HPTP offers several distinct benefits.

- Shelf stability: Enables production of fully shelf-stable products.

- Spore inactivation: Effectively inactivates spores that are resistant to HPP alone.

- Extended shelf life: Provides longer-lasting products.

- Higher microbial inactivation: Combines pressure and heat for a more robust kill step.

While both technologies are based on high pressure, HPP and HPTP cannot be compared as they have two different market purposes, said Bermudez.

"HPP is best compared to traditional thermal pasteurization," he explained. "Whereas HPTP aligns more closely with sterilization methods such as retorting — but with the added benefit of reduced thermal damage to product quality."